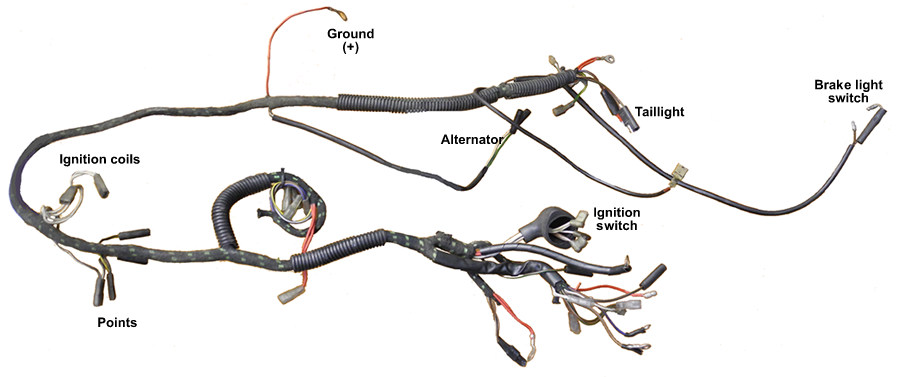

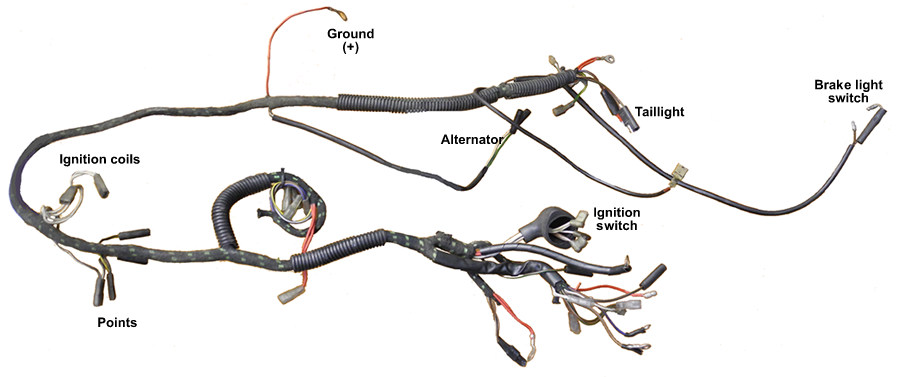

British Wiringing harness, installed 2006, removed 2015

British Wiringing harness, installed 2006, removed 2015

By the time Bonnie turned 37 years and 33,000 miles old in 2006 her wiring harness was showing quite a few signs of wear. That winter I powder coated the frame and since I had to remove the harness anyway, I decided to replace it.

British Wiringing harness, installed 2006, removed 2015

British Wiringing harness, installed 2006, removed 2015

That year I settled on a reproduction wiring harness from British Wiring, $159 US in 2006. The new harness was a beauty - fit perfectly and worked flawlessly for nearly 10 years before an accidental release of Lucas smoke during, ahem, routine maintenance, began making it fail intermittently.

Don't you hate that word? ... intermittently?

After a few heart-stopping ignition failures on back roads I had to face it - the wiring harness had been compromised. Riding off the beaten track as much as I do, a reliable electrical system is crucial, so I decided to replace the wiring harness again.

A custom wiring harness seemed logical considering the modifications I'd made over time to Bonnie, including replacing ignition points with a Pazon, and replacing the zenner and selenium diodes with a Podtronics. And, too, a stock harness would necessarily include wiring for accessories not used on Bonnie, like horn, dip switch, oil pressure switch, etc. Better to put together a custom harness I decided.

At a cost of $169 US I purchased a really serious bullet connector crimping tool, twice as much wire as I had estimated it would require, and plenty of bullets, spade and ring connectors, insulators, etc.

Besides including only the wires that Bonnie needs where she needs them, the custom harness is made with a heavier gauge wire all around, is twin-fused, and includes a multi-point running ground.

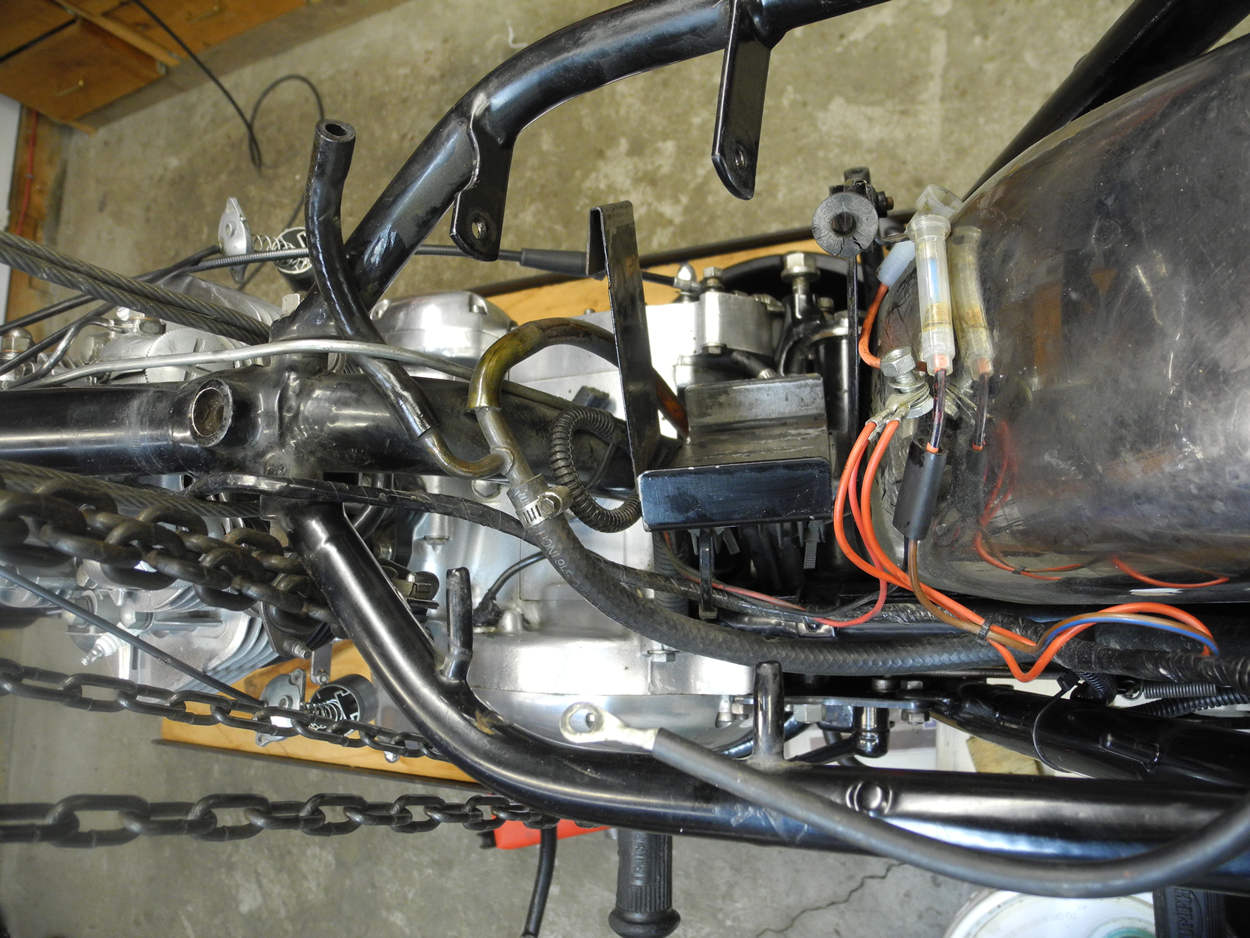

Running the wires

Running the wires

Lucas, Wassel, and British Wiring all use 14-strand wire throughout their 'off-the-shelf' harnesses. The 14-strand wire they use has a max current rating of 8.5 amps; even a momentary short instantly toasts these wires and melts their insulation. (Go ahead, ask how I know). Therefore, I decided on using 28-strand wire throughout. The sole difficulty I encountered using heavier wire was passing three 28-strand wires through the fender hole for the tailight (I chose to run a dedicated ground wire to the tailight) - tight fit!

In order to simplify future trouble-shooting I made the colors of my wiring match that of the Lucas color-codes. After making measurements on the bike I estimated the number of feet of each color of wire I'd need. It added up to a total of 35 feet, which rounds up to 11 meters. At $1.10 per meter, I ordered 22 meters.

As you can see by the diagram below the wiring is minimal. (Click image to enlarge)

Using the schematic I ran the wires, leaving a little extra length everywhere and using lots of wire ties to hold everything in place temporarily.

Wire ties held things in place until completed and ready for tape

Wire ties held things in place until completed and ready for tape

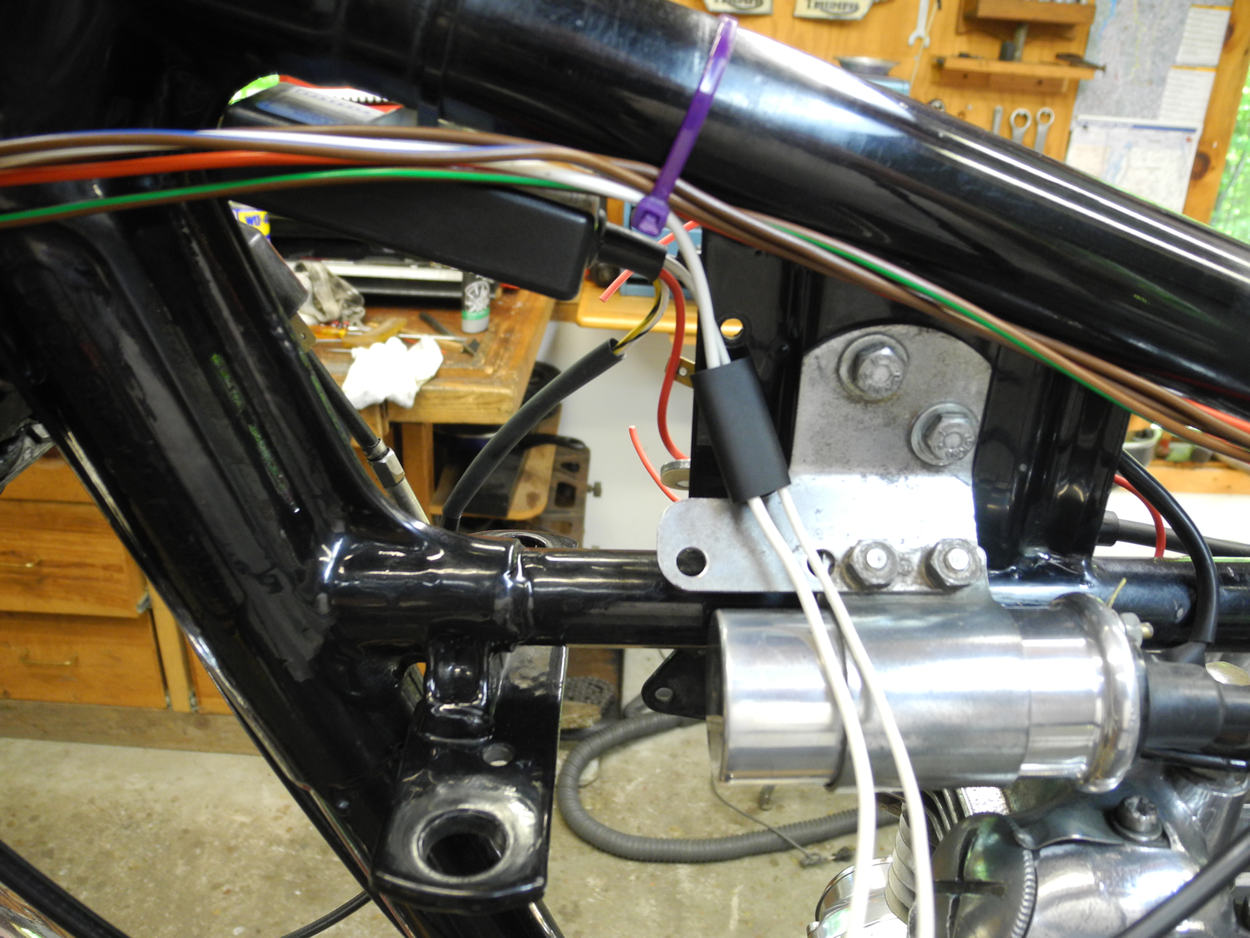

As it is conventionally done, I mounted the Pazon beneath the gas tank.

Pazon mounting

Pazon mounting

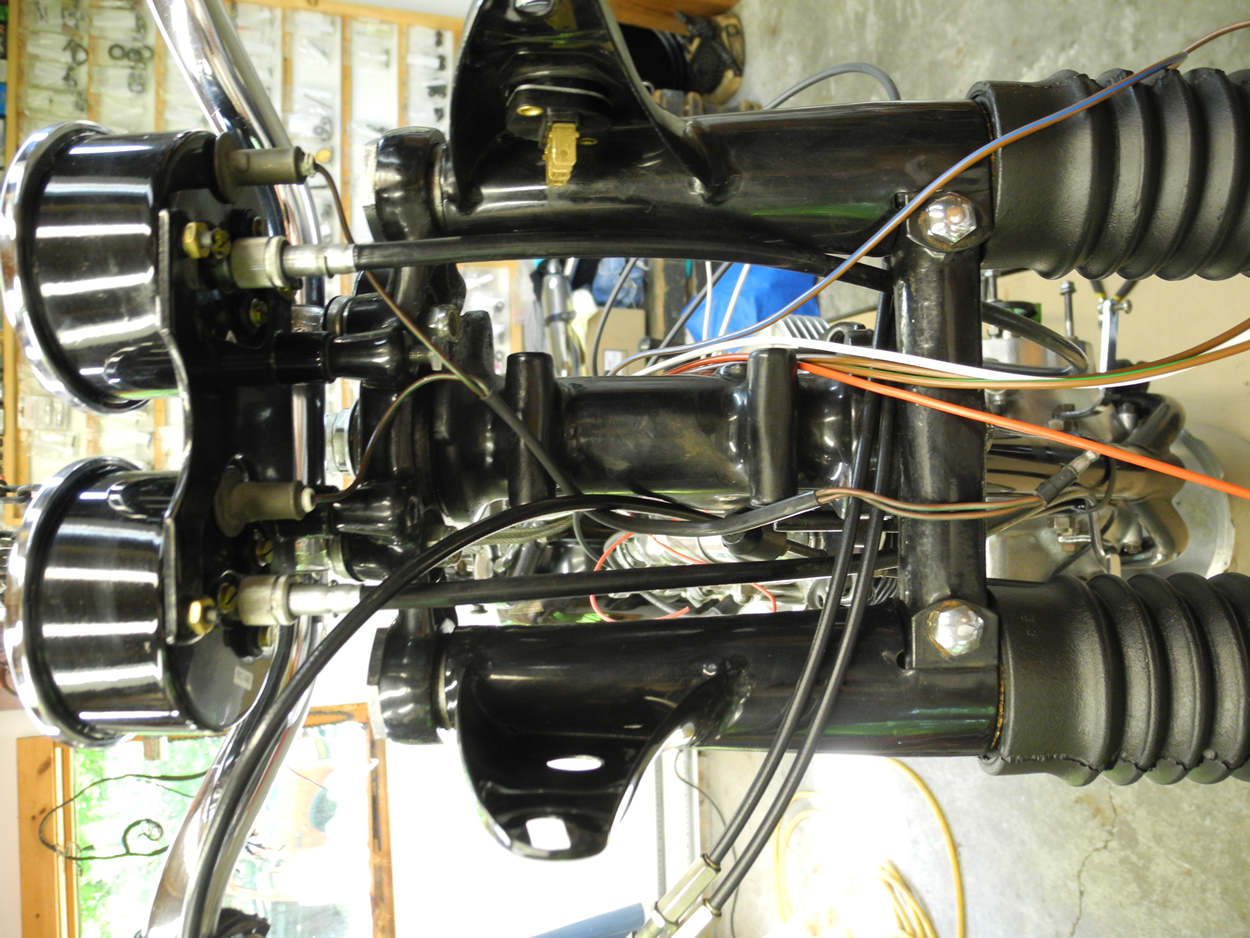

View from the front.

Headlight shell wiring routed through the front fork

Headlight shell wiring routed through the front fork

I wrapped the new harness using a specially designed vinyl tape from British Wiring. The tape has no adhesive, and therefore won't ooze sticky tape goo when heated by summer temperatures and engine heat. Instead, this tape clings to itself and each winding holds the previous one in place, with the ends secured by a short piece of electricians' tape.

I was skeptical about using this tape, but after doing so I'm a convert - besides holding up really well and being easy to clean off with a damp rag, this tape can be easily removed for making harness modifications or repairs without leaving behind a mess.

Wires wrapped with no-adhesive vinyl tape

Wires wrapped with no-adhesive vinyl tape

Photo under gas tank DS wrapped

Vinyl covering looks nearly new after five years

Vinyl covering looks nearly new after five years

Pazon & coils from TS.

Pazon coil setup

Pazon coil setup

The harness splitting at the head stock.

Loom splits at the head stock

Loom splits at the head stock

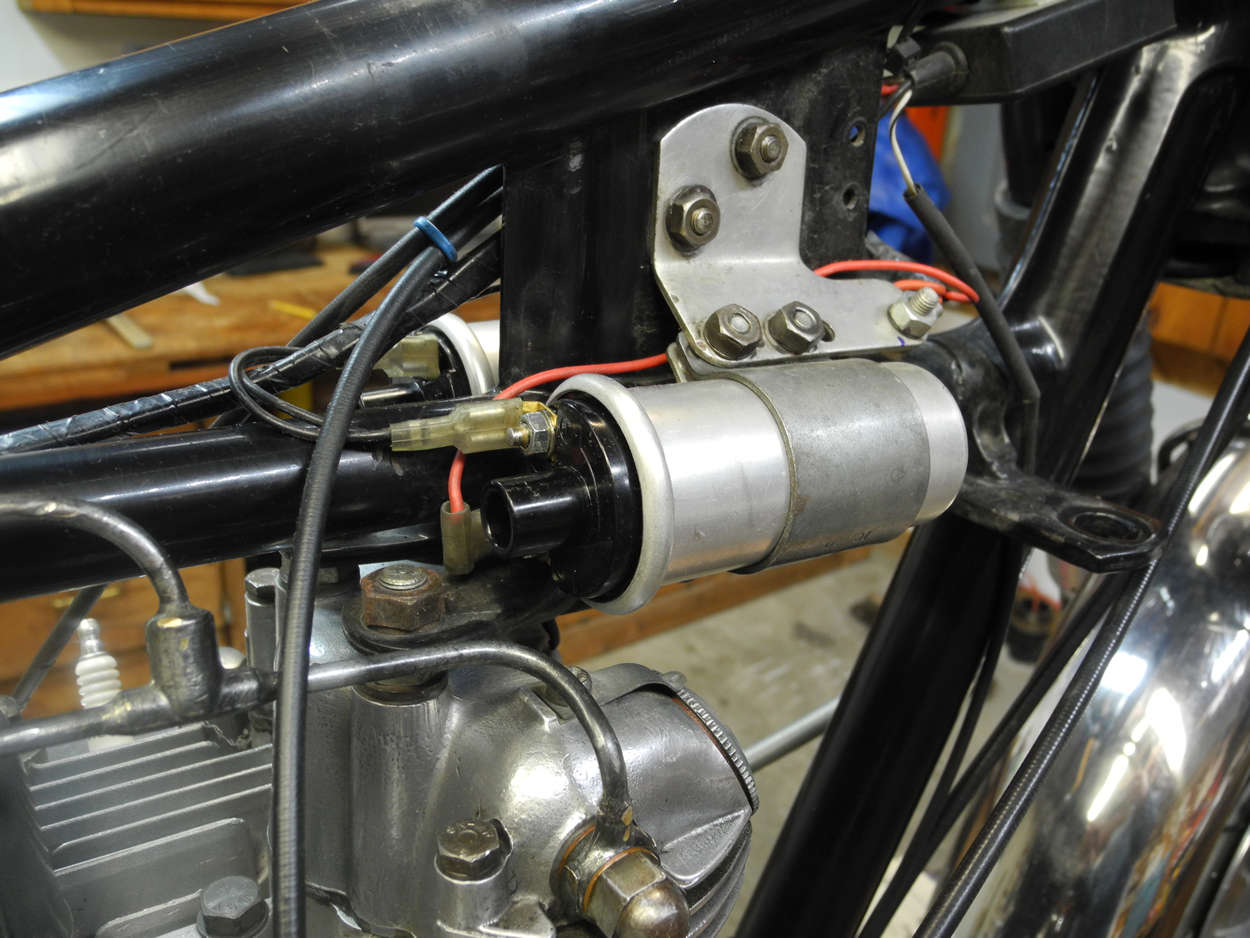

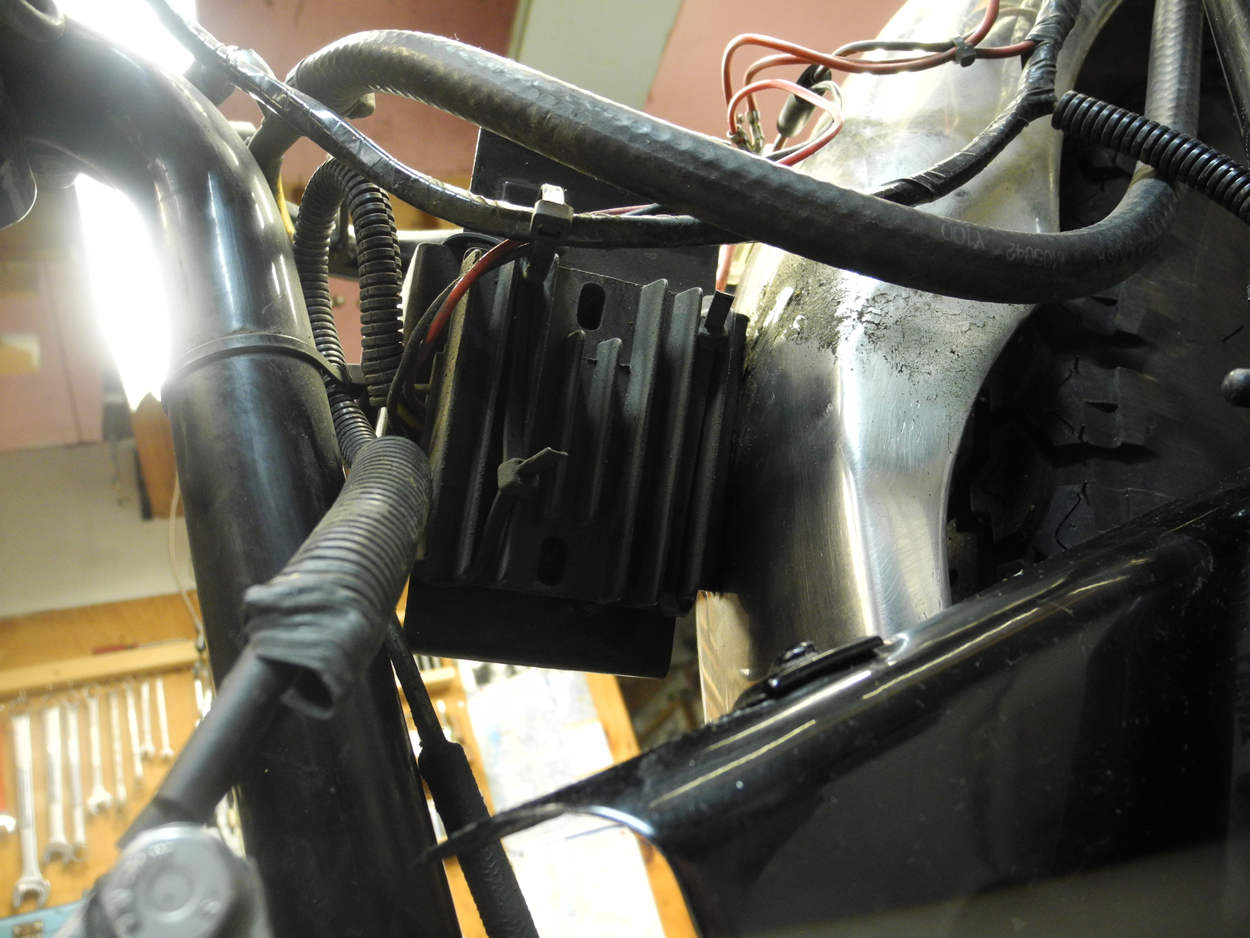

I mounted a Podtronics rectifier/regulator unit beneath the battery carrier, using wire ties to secure it to the carrier.

Podtronics tie-wrapped to bottom of battery carrier

Podtronics tie-wrapped to bottom of battery carrier

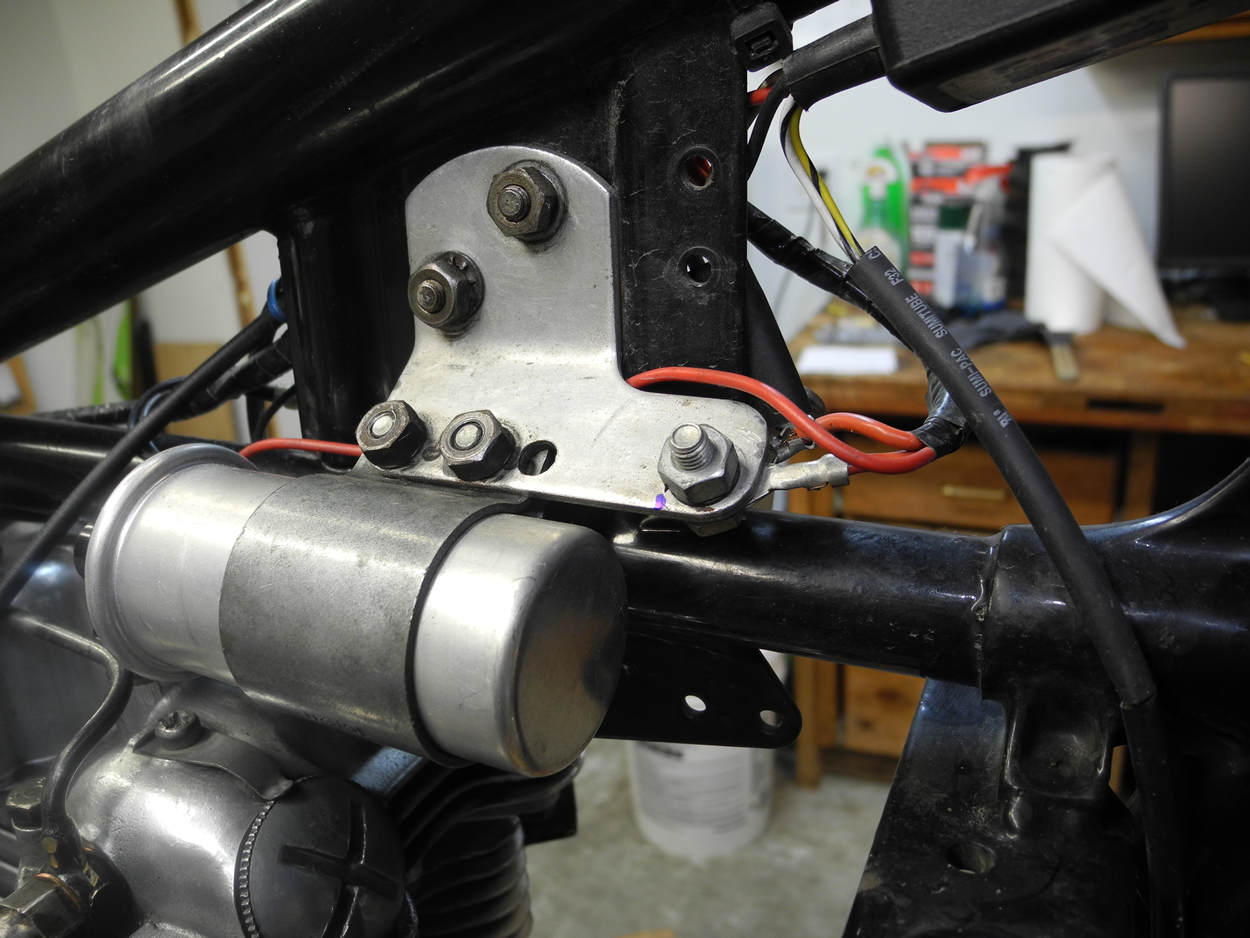

I used the now vacant mounting tab for the selenium rectifier to create a common ground beneath the seat. In addition to connecting this point to the battery's positive terminal, I also ran ground wires from it to the stop/taillight, the headlamp shell, and another grounding point beneath the gas tank.

Common ground beneath the seat

Common ground beneath the seat

This ground point beneath the gas tank is wired directly to the battery ground point beneath the seat.

Common ground beneath the gas tank

Common ground beneath the gas tank