Classic View (fits all)

TOC View (not mob-friendly)

A Hyperlink Junkie's Illustrated Field Guide

to the 1969 Triumph Bonneville

Manual/Tech Bulletin

Manual/Tech Bulletin

Parts Illustration

Parts Illustration

Special Tool

Special Tool

Photo

Photo

WWW Link

WWW Link

Video

Video

LH Thread

LH Thread

Tips

Tips

Traps

Traps

Compatibility

Compatibility

See Documents Section above.

Foot-pounds or pound-feet? Either gets the message across, but technically only one is correct for fastener and engine torque.

Phone numbers are as dialed from North America.

More parts sources plus over two-hundred links for services, accessories, books, clubs, history, tools, technical info, and more.

You've leaned on it, heated it and pounded it and that part STILL won't come out! Duh, it's a left-hand thread! Don't drive yourself nuts, consult this illustrated list of the five left-hand fasteners on a 1969 Triumph 650. Or look for the left-hand signs below in The Bonnie Ref.

You've leaned on it, heated it and pounded it and that part STILL won't come out! Duh, it's a left-hand thread! Don't drive yourself nuts, consult this illustrated list of the five left-hand fasteners on a 1969 Triumph 650. Or look for the left-hand signs below in The Bonnie Ref.

Resources

Baconsdozen Kevin C. Bacon's history and descriptions of Whitworth (BSW), BSF, BSC, UNC, UNF, SAE, AF, and BA. Includes Bacon's own size charts with conversions to metric and decimal inch dimensions. A must-read, top to bottom, richly informative.

Baconsdozen Kevin C. Bacon's history and descriptions of Whitworth (BSW), BSF, BSC, UNC, UNF, SAE, AF, and BA. Includes Bacon's own size charts with conversions to metric and decimal inch dimensions. A must-read, top to bottom, richly informative.

JRC Engineering Whitworth and Other British Threads Graham White and Stephen Moore provide historical and technical perspectives on British threads - including a cogent explanation of BSW/BSF wrench sizes!

JRC Engineering Whitworth and Other British Threads Graham White and Stephen Moore provide historical and technical perspectives on British threads - including a cogent explanation of BSW/BSF wrench sizes!

TriumphRat.net "Nuts n' bolts" A thread about nuts and bolts - how can you resist? Some interesting bits on plating, stainless, sizes, threads, and Stuart's run at BSW/BSF wrench sizes.

TriumphRat.net "Nuts n' bolts" A thread about nuts and bolts - how can you resist? Some interesting bits on plating, stainless, sizes, threads, and Stuart's run at BSW/BSF wrench sizes.

Naich.net "Ever Wonder Why Plumbers Get Paid So Much?" Everything you ever wanted to know about BSP. Maybe more.

Naich.net "Ever Wonder Why Plumbers Get Paid So Much?" Everything you ever wanted to know about BSP. Maybe more.

Note that while American wrenches are measured across the flats (AF) of the bolt head, wrenches for the bolts in the British standard thread family are measured by the diameter of the bolt's threads.

Resources

TriumphRat.net Locktite discussion...

TriumphRat.net Locktite discussion...

TriumphRat.net John Healy, the only four places to use Loctite on a Triumph

TriumphRat.net John Healy, the only four places to use Loctite on a Triumph

Where to use Loctite thread locker on a Triumph 650 is a question that will elicit different answers depending upon who is asked.

According to John Healy (see link above), there are just four places to use Loctite on a Triumph 650:

Thomas G. Gunn, Jr., in his seminal 1987 work "Overhaul Manual For 650cc Unit Construction Triumph Motorcycle Engines since 1963", suggests using Loctite in six places:

It's interesting to note that out of John Healy's four places to use Loctite and Thomas G. Gunn Jr.'s six places, the only concurrence between the two lists is the crankcase bolts.

Other disciples have suggested using Loctite on crankcase studs, although in that application it's used more as a sealant than as a thread locker. In addition, amateur Loctite enthusiasts (now who said that?) have devised many other ingenious applications as well.

The most popular Loctite thread locker products (also see chart below for typical applications):

Resources

TriumphRat.net Which Gasket sealer, there are so many

TriumphRat.net Which Gasket sealer, there are so many

TriumphRat.net TR7RVMan on sealants, and how to know if your Hylomar is out of date

TriumphRat.net TR7RVMan on sealants, and how to know if your Hylomar is out of date

TriumphRat.net "T100R gearbox assembly sealant"

TriumphRat.net "T100R gearbox assembly sealant"

Britbike.com "Loctite plastic gasket"

Britbike.com "Loctite plastic gasket"

The following chart, an interpretation/extrapolation of the TriumphRat.net links above, summarizes opinions about which sealant and which thread lockers to use, and where. Green dot items are commonly recommended, while yellow dots indicate that extra caution is required. Red dotted scenarios may best be avoided altogether. Rationale for the classifications should be apparent from the product descriptions that follow.

Some popular sealant products:

Resources

TriumphRat.net "Gaskets" Don't blow a gasket, get good advice here.

TriumphRat.net "Gaskets" Don't blow a gasket, get good advice here.

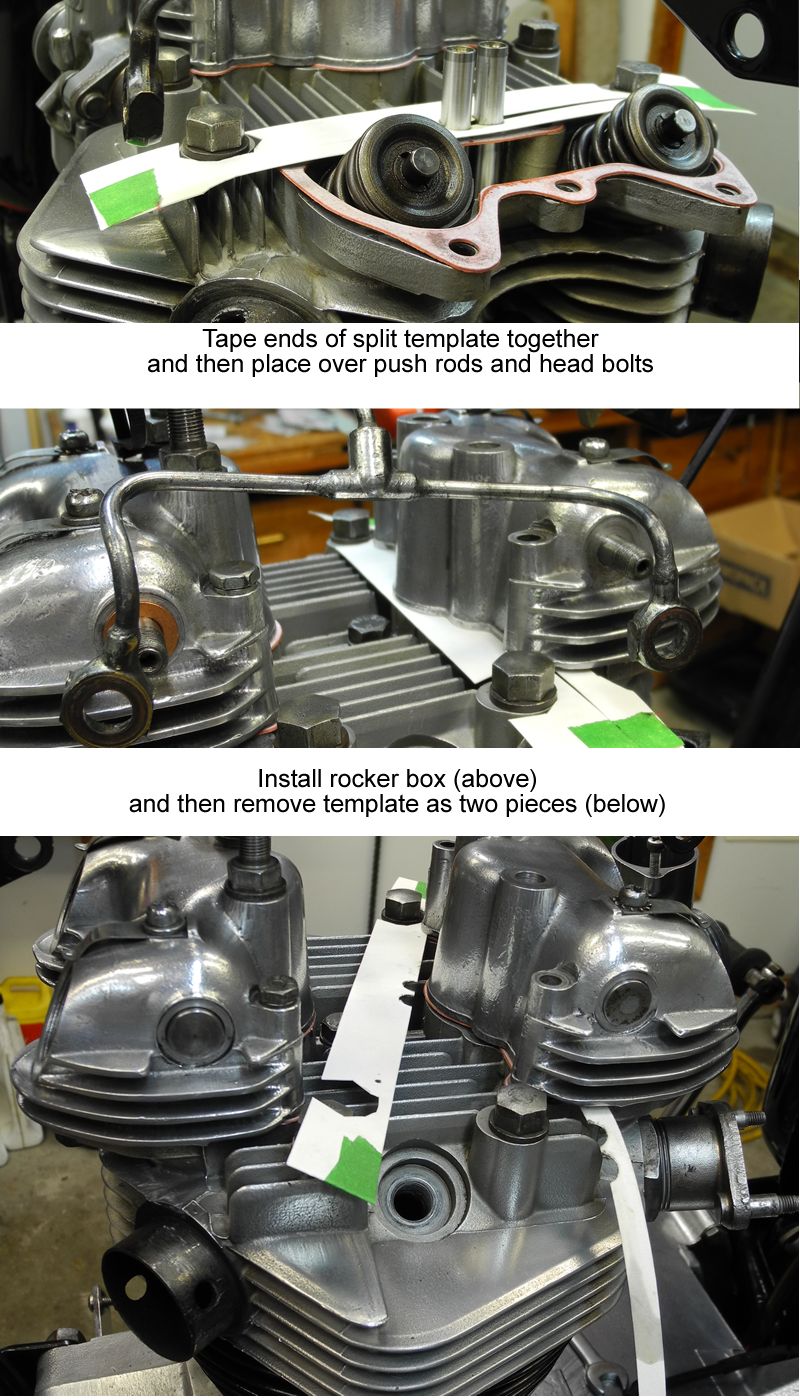

Hermit.cc "Rocker Box Gaskets"

Hermit.cc "Rocker Box Gaskets"

Hermit.cc "Anneal and Install Head Gasket"

Hermit.cc "Anneal and Install Head Gasket"

Hermit.cc "Primary Chaincase Cover and Gasket"

Hermit.cc "Primary Chaincase Cover and Gasket"

| Characteristics / Product | Loctite 641 | Loctite 660 | Loctite 620 |

| Henkel.com Tech Data Sheets | 641 TDS | 660 TDS | 620 TDS |

| Applications | Press fitting, repairing, retaining | High temp slip fitted parts, retaining | |

| Color | Yellow | Silver | Green |

| Cure Type | Anaerobic cure | Anaerobic cure | |

| Fixture Time | 20 min. | 15 min. | 60 min. |

| Gap Fill | 0.15 mm | 0.25 - 0.5 mm | 0.15 - 0.25 mm |

| Strength | Medium strength | High strength, gap filling, thixotropic | Medium to high strength, gap filling, high temperature, high viscosity |

| Operating Temp | 55 - 150C (-65 - 300°F ) | -65 - 300°F (-55 - 150°C ) | -55 - 230C (-65 - 450°F ) |

| Format | Paste | Liquid | |

| Substrates | Metal: Steel | Metal: Steel | Metal: Steel |

| Removal | Requires heat |

Resources

TriumphRat.net Recommended Assembly Lube

TriumphRat.net Recommended Assembly Lube

Assembly lube products are designed to provide lubrification to moving engine parts during initial start-up. An important advantage of assembly lube over motor oil is that while oil will drain away from parts relatively quickly, assembly lube coats parts and remains in place pretty much indefinitely, thus eliminating the need to compress the time between assembly and initial engine start-up.

In the TriumphRat.net thread above, Peg suggests using assembly lube for big ends, piston skirt (very sparingly), cam lobes and bushes, tappet blocks, rocker arms, and valve stems.

Resources

BritBike.com "Heating Engine Cases & Other Parts"

BritBike.com "Heating Engine Cases & Other Parts"

Oven, barbecue, hot tub - your choice.

Resources

Workshop Manual (1969 650cc Twins) Section A: Lubrication Table of Contents

Workshop Manual (1969 650cc Twins) Section A: Lubrication Table of Contents

Workshop Manual (1969 650cc Twins) Section A1: Routine Maintenance

Workshop Manual (1969 650cc Twins) Section A1: Routine Maintenance

Workshop Manual (1969 650cc Twins) Section A2: Recommended Lubricants

Workshop Manual (1969 650cc Twins) Section A2: Recommended Lubricants

Oil products have changed a great deal since the '60s. The WS Manual lubricant recommendations are outdated and obsolete. For modern oil recommendations see individual sections below.

Oil products have changed a great deal since the '60s. The WS Manual lubricant recommendations are outdated and obsolete. For modern oil recommendations see individual sections below.

Resources

Workshop Manual (1969 650cc Twins) Section A3: Engine Lubrication

Workshop Manual (1969 650cc Twins) Section A3: Engine Lubrication

Hermit.cc Percentage of Zinc Content for Popular Oils

Hermit.cc Percentage of Zinc Content for Popular Oils

TriumphRat.net Comments & recommendations (UK & US) on crankcase oil/ZDDP (zinc) and gearbox oil/yellow metals

TriumphRat.net Comments & recommendations (UK & US) on crankcase oil/ZDDP (zinc) and gearbox oil/yellow metals

BritBike.com Very informative synthetic oil thread

BritBike.com Very informative synthetic oil thread

540ratblog "Motor Oil Engineering Test Data"

540ratblog "Motor Oil Engineering Test Data"

Britbike.com "Crankcase vent tube discharge question" TR7RVMan elucidates upon Triumph crankcase venting

Britbike.com "Crankcase vent tube discharge question" TR7RVMan elucidates upon Triumph crankcase venting

Hemmings.com "Tech 101: Zinc in oil and its effects on older engines"

Hemmings.com "Tech 101: Zinc in oil and its effects on older engines"

According to an article ("Tech 101: Zinc in oil and its effects on older engines"), modern oil manufacturers have reduced the amount of 'zinc' (actually ZDDP [zinc dialkyldithiophosphate] or ZDTP [zinc di-thiophosphate]) in their products for various reasons, including prolongation of the life of catalytic converters. When used in older (classic) car and motorcycle engines, the low-zinc products fail to provide sufficient protection against start-up engine wear.

Here's a list that gives zinc content of a few oils on the market, In relatively cool climates, Shell Rotella 15w-40 seems to work quite well.

Resources

Workshop Manual (1969 650cc Twins) Section A4: Changing the Engine Oil & Cleaning the Filters

Workshop Manual (1969 650cc Twins) Section A4: Changing the Engine Oil & Cleaning the Filters

Triumph specified an engine oil change interval of 1,500 miles. Of course the only oil filtering back in the day was the wire screens in the oil tank and the crankcase.

Even after I installed an external oil filter (see "Using an Oil Filter" just below), I continued changing engine oil (and filter) at 1,000 mile intervals. And to simplify things I change crankcase oil and primary chaincase oil at the same time. So far, oil changes are cheaper than engine rebuilds!

Capacity

Drain bolts

Some point out the difficulty in cleaning thoroughly around the crankcase oil drain plug due to its proximity to the crankcase joint and the angle at which they meet. They suggest that removing the crankcase drain bolt is a bad idea because of the attendant risk of contaminating engine oil with dirt.

Since only a small amount of oil (less than a quarter of a cup) drains out of the crankcase anyway, I adopted the practice of removing the drain plug once a year during winter maintenance to inspect and clean the filter screen. The same goes for the filter screen in the oil tank.

Resources

Glenn "Phrog" Davidson's Norton filter head mounting bracket design

Glenn "Phrog" Davidson's Norton filter head mounting bracket design

Colorado Norton Works Oil Filter Adaptor for Norton Filter Head

Colorado Norton Works Oil Filter Adaptor for Norton Filter Head

Probably the single most important modification one can make to a classic British bike is to install a modern external oil filter. It has been said that doing so can quadruple the life of an engine. That estimation may be slightly exaggerated, but there's no doubt about the extra protection afforded to an engine by an add-on oil filter

The most common retro-fit oil filter system utilizes a Norton-type oil filter head, connected in the return oil line between the oil pump and the oil tank, as diagrammed below.

The go-to mounting bracket design is that of Glenn Davidson (see link above). The oil filter head and Davidson-style mounting bracket are commonly mounted at the bottom of the down tube, facing the rear of the bike at a height which gives just enough clearance between the filter and the center stand in both it's up and down positions. It may be necessary to grind just a bit off the "lump" at the bottom of the downtube.

Note that the Triumph oil tank connections and oil pipe junction block pipes are 1/4", while those of the Norton filter head are 3/8". The compromise is to use 5/16" (automatic transmission cooler) hose to make the connections between the filter head and the oil tank and oil junction block. It is a very tight fit on the filter head's 3/8" fittings, and somewhat loose on the 1/4" pipes of the oil tank and oil junction block, but once they are well-clamped the connections shouldn't leak.

Another possiblity is to replace the Norton filter head's 3/8" stubs with 1/4" ones. This mod was performed on my Bonnie's filter head recently so now I use 1/4" hose throughout.

The following filters work satisfactorily with the Norton filter head, and others can be found on cross-reference lists online.

A simple double-threaded adaptor is available from Colorado Norton Works (see link above) which permits use of more widely available and potentially less expensive oil filters, such as the following:

Resources

Workshop Manual (1969 650cc Twins) Section A8: Removing & Replacing the Oil Pipe Junction Block

Workshop Manual (1969 650cc Twins) Section A8: Removing & Replacing the Oil Pipe Junction Block

Workshop Manual (1969 650cc Twins) Section A9: Removing & Replacing the Rocker Oil Feed Pipe

Workshop Manual (1969 650cc Twins) Section A9: Removing & Replacing the Rocker Oil Feed Pipe

Incorrect installation of oil lines will result in catastrophic damage to an engine.

Incorrect installation of oil lines will result in catastrophic damage to an engine.

The oil pipe junction block connections described here are only for Triumph unit 650s. No less an authority than Mr. Pete informs us that connections for pre-unit Triumphs are the exact opposite.

In the following descriptions of oil line connections, "front" and "forward" reference towards the front of the motorcycle, and "rear" and "back" reference towards the rear of the motorcycle.

The feed line is the rear oil line connection on the oil tank (union nut). The feed line goes to the forward connection pipe on the oil junction block. So oil tank rear to oil junction block forward. (Refer to illustration just below).

The return oil line is the front connection on the oil tank. It goes to the oil junction block's rear connection pipe. So oil tank front to oil junction block rear. (Refer to illustration just below).

Oil to the rockers was fed from the oil tank tower in 1966 - in all other years, before and after, the feed is taken from the scavange return at the bottom of the tank.

Incorrect installation of oil lines will result in catastrophic damage to an engine.

Incorrect installation of oil lines will result in catastrophic damage to an engine.

A Norton oil filter head is ordinarily installed in the return oil line as per the following diagram.

Removing the oil lines from the oil junction block tubes can be a bit difficult, especially if they have been undisturbed for a long time. The job can be made a little easier by removing the outer gearbox cover first.

In any case, it is wise to heed the WS Manual's explicit warning to avoid over-stressing the tubes.

Resources

BritBike.com "Crankcase breather check?" A real pro tells how to test the engine's disc breather.

BritBike.com "Crankcase breather check?" A real pro tells how to test the engine's disc breather.

A 3/8" plastic tubing (70-5375 Ref# 39 Fig.2 #7) connects the engine breather pipe stub (70-2724 Ref# 7 Fig.2 #7) just forward of the gearbox sprocket to the Tee (70-5370) near the top of the oil tank. Also connected to the tee is the oil tank vent pipe ( 70-6356, Ref# 16 Fig.23 #7), and the oil breather vent tube (82-7353, Ref# 18 Fig.23 #7)

The engine breather stub is in a constrained, out-of-the-way location. The best time to put the plastic tubing on it is with engine out of the frame.

The engine breather stub is in a constrained, out-of-the-way location. The best time to put the plastic tubing on it is with engine out of the frame.

If the engine's in the frame, this tip makes child's play of a #!@*& job: fasten a 1/4" or 5/16" wooden dowel about 10 inches long to the end of the tubing with masking tape and use it to push the tubing onto the stub. Work from the TS; prop up a mirror beneath the engine; shine a light up there. Putting the dowel toward the rear lets you see and lets you scrape along it with a sharp blade to remove by twisting. If a little tape gets left behind, no biggie.

The oil breather vent tube passes on the left side just above the indentation in rear fender.

The first clamp is fastened on the left-hand side beneath the left nut holding the strap on top of the fender between the two upper shock mounts.

Resources

Workshop Manual (1969 650cc Twins) Section B33: Remove/Replace Oil Pump

Workshop Manual (1969 650cc Twins) Section B33: Remove/Replace Oil Pump

Workshop Manual (1969 650cc Twins) Section A7: Stripping and Reassembling the Oil Pump

Workshop Manual (1969 650cc Twins) Section A7: Stripping and Reassembling the Oil Pump

Triumph Overhaul Manual Assembling the Oil Pump

Triumph Overhaul Manual Assembling the Oil Pump

Britbike.com "Oil Pump Confusion Unit 650cc SOLVED!"

Britbike.com "Oil Pump Confusion Unit 650cc SOLVED!"

Although Triumph made several changes to 650/750 oil pumps, they are all interchangeable according to John Healy.

Although Triumph made several changes to 650/750 oil pumps, they are all interchangeable according to John Healy.

| Year | Part No | Specs |

| 1963 - 1966 | E3878 | Scavenge 0.437"/ Feed 0.374" |

| 1967 - Early 1969 | E6928 | Scavenge enlarged to 0.487"/ Feed 0.374" |

| Late 1969 - 1979 | E9421 | Scavenge 0.487"/ Feed enlarged to 0.406" |

| 1980 and on | 71-7317 | Double check-valve pump (Scavenge& Feed unchanged: Scavenge 0.487"/ Feed 0.406") |

| Source: Britbike.com | ||

Resources

Workshop Manual (1969 650cc Twins) Section A5: Oil Pressure

Workshop Manual (1969 650cc Twins) Section A5: Oil Pressure

Workshop Manual (1969 650cc Twins) Section A6: Stripping and Reassembling the Oil Pressure Release Valve

Workshop Manual (1969 650cc Twins) Section A6: Stripping and Reassembling the Oil Pressure Release Valve

Triumph Overhaul Manual Assembling the Oil Pressure Relief Valve

Triumph Overhaul Manual Assembling the Oil Pressure Relief Valve

Resources

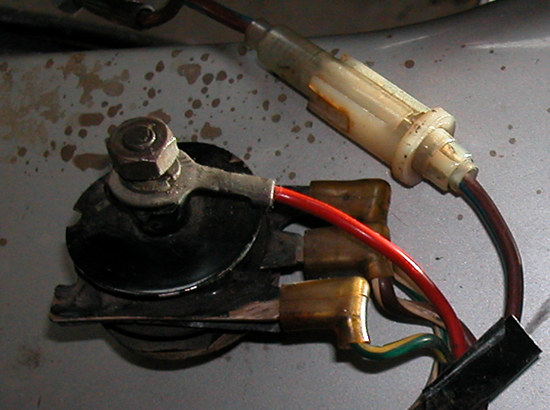

Workshop Manual (1969 650cc Twins) Section H18: Oil Pressure Switch

Workshop Manual (1969 650cc Twins) Section H18: Oil Pressure Switch

The Bonneville Shop forum "A Guide for BSA and Triumph Oil Pressure Switch Identification", Dave Porter.

The Bonneville Shop forum "A Guide for BSA and Triumph Oil Pressure Switch Identification", Dave Porter.

TriumphRat forum Oil pressure switch for '70 T120?.

TriumphRat forum Oil pressure switch for '70 T120?.

TriumphRat forum Excerpt from another oil pressure switch thread.

TriumphRat forum Excerpt from another oil pressure switch thread.

If so desired, the oil pressure switch can be removed and replaced by a blanking plug.

When fitting either a replacement oil switch or a blanking plug, care must be taken to insure that its threads correspond correctly to those of the timing cover. Most timing covers are made for straight threads, but threads in some are tapered. Consult the links above to determine the correct part for your bike.

Caution! Fitting a straight-threaded part into a tapered-threaded cover can easily result in a cracked timing cover!

Caution! Fitting a straight-threaded part into a tapered-threaded cover can easily result in a cracked timing cover!

Resources

Workshop Manual (1969 650cc Twins) Section E2: Removing and Replacing the Oil Tank

Workshop Manual (1969 650cc Twins) Section E2: Removing and Replacing the Oil Tank

Battery Carrier/Oil Tank Mounting (2 photos)

Battery Carrier/Oil Tank Mounting (2 photos)

TriumphRat.net A thread with some interesting info on oil tanks, oil pumps, and oil flow

TriumphRat.net A thread with some interesting info on oil tanks, oil pumps, and oil flow

Britbike.com A thread on repairing Triumph oil tanks

Britbike.com A thread on repairing Triumph oil tanks

Britbike.com Another oil tank repair thread

Britbike.com Another oil tank repair thread

BritBike.com Some ideas on cleaning oil tanks

BritBike.com Some ideas on cleaning oil tanks

From 1967 to 1970 the unit 650 Triumph oil tank was unchanged. However, according to RF Whatley, Triumph made several modifications to engine lubrication in 1966, including a new (and problematic) oil tank design. Whatley tells us that the modified design was limited to several months of production and most were changed under warranty. However, an oil tank with the rocker feed coming off the top instead of the bottom is of the problematic 1966 design and should be replaced with a later model.

From 1967 to 1970 the unit 650 Triumph oil tank was unchanged. However, according to RF Whatley, Triumph made several modifications to engine lubrication in 1966, including a new (and problematic) oil tank design. Whatley tells us that the modified design was limited to several months of production and most were changed under warranty. However, an oil tank with the rocker feed coming off the top instead of the bottom is of the problematic 1966 design and should be replaced with a later model.

Use Murphy's liquid soap on the rubber parts to help ease them in.

Important that tank "hangs" well to avoid rubbing and consequential wear.

One would think that the rubber mounting would incur the wear, but the wear that occurred after my very first re-assembly was to the tank's mounting peg, not the rubber.

A proper adjustment is obtained by rotating the "C" clamp mounting bracket until all parts of the tank are suspended clear of the frame.

In case you ever need to know, HenryAnthony on Britbike.com forum informs us that the measurement between the barrels holding the rubber upper mounts is 4-1/4", and the measurement between the battery holder straps they bolt up to is 4-1/2".

Resources

Workshop Manual (1969 650cc Twins) Section A21: Check Procedure for Wet Sumping

Workshop Manual (1969 650cc Twins) Section A21: Check Procedure for Wet Sumping

TriumphRat.net Peg explains Triumph oil pump operation and describes wet sumping and oil drain down and their causes.

TriumphRat.net Peg explains Triumph oil pump operation and describes wet sumping and oil drain down and their causes.

Resources

Workshop Manual (1969 650cc Twins) Section A12: Primary Chaincase Lubrication

Workshop Manual (1969 650cc Twins) Section A12: Primary Chaincase Lubrication

Oil change info below does not apply to engines made after late 1969. Prior to that time, crankcases and primary chaincases were completely separate from each other, and each had their own oil supply. But starting in late 1969, Triumph modified crankcase breathing by venting the crankcase into the primary chaincase, and thus the two began sharing a common oil supply.

Oil change info below does not apply to engines made after late 1969. Prior to that time, crankcases and primary chaincases were completely separate from each other, and each had their own oil supply. But starting in late 1969, Triumph modified crankcase breathing by venting the crankcase into the primary chaincase, and thus the two began sharing a common oil supply.

The late 1969 changes weren't documented in parts books or manuals until 1970. Therefore, if your engine is a late 1969 that shares oil, consult 1970 documentation for parts and oil change info.

While it is a common practice to use ATF primary chain case lube in engines whose crankcases and chain cases are separate, attempting to do so on engines that share oil between engine and primary chaincase would be disastrous. Know what you got.

While it is a common practice to use ATF primary chain case lube in engines whose crankcases and chain cases are separate, attempting to do so on engines that share oil between engine and primary chaincase would be disastrous. Know what you got.

Change primary chaincase oil at 1,000 mile intervals. Drain and replace with 350cc of 30w non-detergent oil.

As noted just above, a fairly common practice is to replace non-detergent primary chaincase oil with ATF - but NOT on units that share oil between engine and primary.

The chaincase oil drains slowly because it needs to flow past the primary chain tension adjuster. The drip, drip, drip flow of oil even when it's hot takes hours so I usually give it all day or overnight.

Avoid damaging threads in the soft aluminum case, go easy tightening the drain bolt.

Avoid damaging threads in the soft aluminum case, go easy tightening the drain bolt.

If the volume of oil drained from the primary exceeds what was put in, it is likely an indication of a failed DS crankshaft seal allowing passage of engine oil into the chaincase.

If the volume of oil drained from the primary exceeds what was put in, it is likely an indication of a failed DS crankshaft seal allowing passage of engine oil into the chaincase.

Resources

Workshop Manual (1969 650cc Twins) Section A11: Gearbox Lubrication

Workshop Manual (1969 650cc Twins) Section A11: Gearbox Lubrication

MachineryLubrication.com "The Effects of EP Additives on Gearboxes"

MachineryLubrication.com "The Effects of EP Additives on Gearboxes"

Lucas oil representative 'Don't use our products with yellow metal' (2014)

Lucas oil representative 'Don't use our products with yellow metal' (2014)

Britbike.com "Bronze-friendly gear oil recommendation?"

Britbike.com "Bronze-friendly gear oil recommendation?"

TriumphRat.net Comments & recommendations (UK & US) on crankcase oil/ZDDP (zinc) and gearbox oil/yellow metals

TriumphRat.net Comments & recommendations (UK & US) on crankcase oil/ZDDP (zinc) and gearbox oil/yellow metals

Hermit.cc Hermit's Gearbox Oil/Yellow Metal Experiment, with conclusion.

Hermit.cc Hermit's Gearbox Oil/Yellow Metal Experiment, with conclusion.

Opinions differ about using GL5 spec gear oils around the yellow metal bushings and thrust washers used in our Triumph gearboxes.

GL5 oils have high concentrations of sulphur and sulphur reacts with yellow metals chemically to break them down. So say those who believe GL5 is harmful. Yet many others say they've used GL5 for years without problems.

Why take a chance? I was always disinclined to use GL5 gear oil in my Bonnie's gearbox.

Oil companies say GL5 products are now safe because they've reduced active sulphur, which eats yellow metals, in favor of inactive sulphur, which is less harmful while still providing the protective qualities of active sulphur.

I don't find "less harmful" all that reassuring, frankly.

However, since doing my own yellow metal and GL5 experiment I do feel a bit more comfortable about GL5. But I still prefer good old GL4.

For those who harbor doubts, the following list of oil descriptions are those which are said to be, at least potentially, harmful to yellow metals:

For other gear oil recommendations (including many in UK) see this link above in TriumphRat.

There are three hex heads on the bottom of the gearbox: the 3/4" index plunger holder (57-2172); the 7/16BS (3/8W) drain plug with level tube (57-3851); and the 5/16" gearbox level plug (21-0543).

The level plug threads into the drain plug and together they are tucked just inside the frame member on the timing side. Since they are closer to the timing side I always removed and installed them from that side. However, access from that side is awkward due to the proximity of the frame, and recently I realized that it's actually easier to access them from the drive side.

To drain the oil, remove the drain bolt using a 7/16BS (3/8W) socket and a two or three inch extension to clear the frame. Remove carefully to avoid damage to the level tube extending above the drain bolt.

When replenishing the gearbox oil, replace the drain plug after removing the level plug and then add oil, slowly when approaching 500ml, until it overflows from the level plug.

Resources

BritBike.com " How to stop oil and gear box drain plug leaks?".

BritBike.com " How to stop oil and gear box drain plug leaks?".

Resources

Workshop Manual (1969 650cc Twins) Section A16: Front Fork Lubrication

Workshop Manual (1969 650cc Twins) Section A16: Front Fork Lubrication

Gavin Eisler's tip on draining fork oil:

Gavin Eisler's tip on draining fork oil:

"When changing fork oil remove RHS top nut, remove LHS drain screw, doing opposites stops oil gushing out the top as the bike settles. Read that in the manual, after doing it wrong for years, this saves a lot of mess. I like to flush the old oil with a little kerosene to get the last of the muck out."

Resources

Workshop Manual (1969 650cc Twins) Section A10: Contact Breaker Lubrication

Workshop Manual (1969 650cc Twins) Section A10: Contact Breaker Lubrication

Note that the nipple on the speedometer gearbox grease fitting is not a standard size. However, a standard grease gun will inject a sufficient amount of grease to keep the gearbox well-lubed according to Stuart.

And in another post Stuart alerts us to this grease nipple source.

Resources

Triumph Workshop Manual 1969 Unit 650 c.c. Section B: The Engine

Triumph Workshop Manual 1969 Unit 650 c.c. Section B: The Engine

Triumph Overhaul Manual 650cc Unit since 1963

Triumph Overhaul Manual 650cc Unit since 1963

Triumph Overhaul Manual Engine Changes Relating to Major Engine Work

Triumph Overhaul Manual Engine Changes Relating to Major Engine Work

Triumph Overhaul Manual Service Tools for Complete Overhaul

Triumph Overhaul Manual Service Tools for Complete Overhaul

Fig.14 Engine Mounting Plates, Footrests

Fig.14 Engine Mounting Plates, Footrests

Britbike.com "Torque wrench settings", Rod bolt stretch, tappets & cams

Britbike.com "Torque wrench settings", Rod bolt stretch, tappets & cams

TriumphRat.net Advice on preparing for a complete engine tear down

TriumphRat.net Advice on preparing for a complete engine tear down

TriumphRat.net Engine Rebuilding Guys in the know tell us what to look for when rebuilding an engine (must-read)

TriumphRat.net Engine Rebuilding Guys in the know tell us what to look for when rebuilding an engine (must-read)

Triple Cycles, UK

"Waking the Sleeping Beast" Starting an engine after a long sleep. Note: this article was written for Triples. StuartMac cautions us to add just one pint and not two to a Twin's craankcase through the primary chaincase since its crankcases is smaller,

Triple Cycles, UK

"Waking the Sleeping Beast" Starting an engine after a long sleep. Note: this article was written for Triples. StuartMac cautions us to add just one pint and not two to a Twin's craankcase through the primary chaincase since its crankcases is smaller,

Hermit's index to Lowbrow's 13-part 650 Rebuild Video Series.

Hermit's index to Lowbrow's 13-part 650 Rebuild Video Series.

Resources

CycleWorld "What Is The Difference Between Normal And Abnormal Combustion In A Motorcycle Engine?" An overview.

CycleWorld "What Is The Difference Between Normal And Abnormal Combustion In A Motorcycle Engine?" An overview.

Allen W. Cline, CONTACT! Magazine

"Engine Basics: Detonation and Pre-Ignition" Detailed explanation.

Allen W. Cline, CONTACT! Magazine

"Engine Basics: Detonation and Pre-Ignition" Detailed explanation.

Descriptions of pre-ignition and detonation found in the article and video above can be summarized this way:

"Generally detonation witness marks are not left in the center of the piston, they tend (note:I did not say always) to show up at the edge of the piston. Light detonation can most times be tolerated by a piston, heavy detonation often collapses the piston ring lands." Peg, Triumphrat.net

"Generally detonation witness marks are not left in the center of the piston, they tend (note:I did not say always) to show up at the edge of the piston. Light detonation can most times be tolerated by a piston, heavy detonation often collapses the piston ring lands." Peg, Triumphrat.net

"Marks in the center of the piston are more likely to be the result of Pre-Ignition, a much more sinister problem. This problem tends blows holes in your piston crown, it destroys in seconds. (Pre ignition can be brought about by the heat generated by detonation)." Peg, TriumphRat.net

"Marks in the center of the piston are more likely to be the result of Pre-Ignition, a much more sinister problem. This problem tends blows holes in your piston crown, it destroys in seconds. (Pre ignition can be brought about by the heat generated by detonation)." Peg, TriumphRat.net

Things to beware of:

Kicking back during starting is symptomatic of engine problems and potentially hazardous to the operator. The three most likely causes of kick-back are:

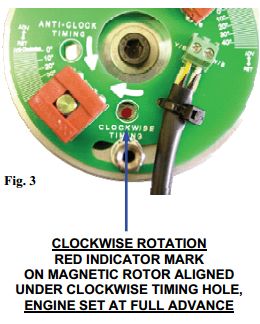

When considering timing advance issues it's wise to first check the alignment of the rotor's 38 degree line with actual TDC using a TDC tool or other method.

Spin speed can be a factor, particularly in the case of electronic ignition systems.

Resources

Workshop Manual (1969 650cc Twins) Section B1: Removing and Replacing the Engine Unit

Workshop Manual (1969 650cc Twins) Section B1: Removing and Replacing the Engine Unit

Hermit.cc Removing engine using chain hoist

Hermit.cc Removing engine using chain hoist

Resources

Workshop Manual (1969 650cc Twins) Section B39: Inspect Crankcase Components

Workshop Manual (1969 650cc Twins) Section B39: Inspect Crankcase Components

Triumph Overhaul Manual Separating Crankcase Assembly

Triumph Overhaul Manual Separating Crankcase Assembly

Triumph Overhaul Manual Assembling the Crankcase Halves

Triumph Overhaul Manual Assembling the Crankcase Halves

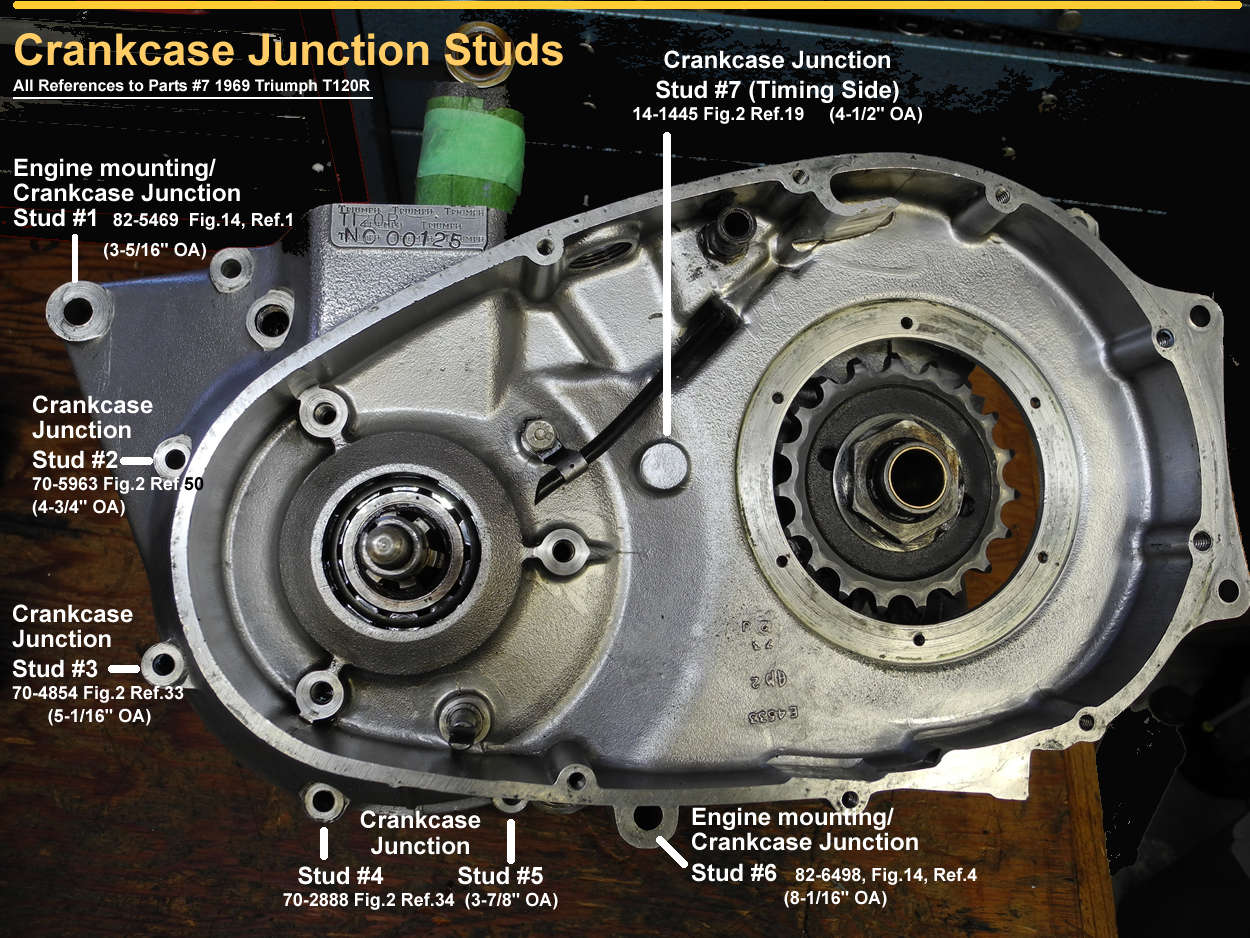

Remove studs using two locked nuts. But use regular nuts, not your 12-point base nuts.

There are ten 14-0303 nuts on the bike. I use a couple of new 14-0303 i keep in spares inventory. (3/8-24TPI UNF)

When studs don't unscrew easily, just a tiny bit of heat on the case releases them right away.

On the 1969 650 engine there are three hollow dowels on the DS case and three more on the TS case. Several parts books, including #7, make a mess of the part numbers, locations, and quantities of these dowels. All the errors are described and corrected in this corrected illustration.

On his Triumph 650 Rebuild DVD, Hughie Hancox shows how to install the hollow dowels on the two crankscase cylinder pad studs with grooves for them: run them down into their crankcase grooves with a base nut. Now, why didn't I think of that?

On his Triumph 650 Rebuild DVD, Hughie Hancox shows how to install the hollow dowels on the two crankscase cylinder pad studs with grooves for them: run them down into their crankcase grooves with a base nut. Now, why didn't I think of that?

Peg shares how to remove hollow dowels without crushing them: "I like to place a bolt in the dowel before gripping it so that it does not collapse, a little wiggle usually gets them out, they are not in very deep."

Peg shares how to remove hollow dowels without crushing them: "I like to place a bolt in the dowel before gripping it so that it does not collapse, a little wiggle usually gets them out, they are not in very deep."

This procedure is after that shown by Hughie Hancox on his "Hughie Hancox Triumph Unit 650" rebuild DVD.

DS Crankcase Assembly

TS Crankcase Assembly

Assemble Cases Together

Resources

Workshop Manual (1969 650cc Twins) Section B36: Dismantle/Reassemble Crankshaft Assembly

Workshop Manual (1969 650cc Twins) Section B36: Dismantle/Reassemble Crankshaft Assembly

Workshop Manual (1969 650cc Twins) Section B37: Stripping & Reassembling the Crankshaft Assembly

Workshop Manual (1969 650cc Twins) Section B37: Stripping & Reassembling the Crankshaft Assembly

Triumph Overhaul Manual Measure crankshaft journals

Triumph Overhaul Manual Measure crankshaft journals

Service Bulletin #67-15 "Roller Bearing (E2879) Crankshaft Drive Side on "B" Range 650cc beg.DU24875"

Service Bulletin #67-15 "Roller Bearing (E2879) Crankshaft Drive Side on "B" Range 650cc beg.DU24875"

Service Bulletin Twin 14/72 "Metric Main Bearings"

Service Bulletin Twin 14/72 "Metric Main Bearings"

TriumphBonneville120.co.uk "Triumph Main Bearings Used by Year and Model" Info on C2, CN, C3

TriumphBonneville120.co.uk "Triumph Main Bearings Used by Year and Model" Info on C2, CN, C3

BritBike.com "Weight of a 650 crank" Very informative thread - highly recommended Triumph crankshaft reading.

BritBike.com "Weight of a 650 crank" Very informative thread - highly recommended Triumph crankshaft reading.

YouTube Lunmad - 650 bottom end inc sludge AND easy gearbox assy All under 20 minutes.

YouTube Lunmad - 650 bottom end inc sludge AND easy gearbox assy All under 20 minutes.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 6 The Crankshaft Begins at: 00:00.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 6 The Crankshaft Begins at: 00:00.

Resources

Workshop Manual (1969 650cc Twins) Section B37: Stripping & Reassembling the Crankshaft Assembly

Workshop Manual (1969 650cc Twins) Section B37: Stripping & Reassembling the Crankshaft Assembly

Triumph Overhaul Manual Installing the Sludge Trap

Triumph Overhaul Manual Installing the Sludge Trap

VintageBikeMagazine.com "Removing Trumph Sludge Tube" Text and Photos

VintageBikeMagazine.com "Removing Trumph Sludge Tube" Text and Photos

Lowbrow "How to Remove the Trumph Sludge Trap Tube" Text and Photos

Lowbrow "How to Remove the Trumph Sludge Trap Tube" Text and Photos

Lowbrow Triumph 650 Disassembly & Rebuild: Part 6 Sludge Trap Removal Begins at: 09:25.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 6 Sludge Trap Removal Begins at: 09:25.

The sludge trap is a metal tube fitted inside the gallery that runs through the big end connecting rod journals. Oil is forced through the timing end of the crankshaft and through oil passageways into the sludge tube. There, centrifugal force separates the particles suspended in the oil - think of a washer in spin cycle with bras and panties flattened while the water flows away. Well, maybe not such a great analogy. Anyway, inboard weep holes permit the oil to lubricate the big end bearings and then return to the crankcase sump from where it's pumped back to the reservoir.

Although it's controversial and frequently maligned, the Triumph sludge trap is actually a relatively effective oil filter. Its big drawback is that it can't be inspected or cleaned without splitting the crankcase - a major job requiring complete disassembly of the transmission and engine, although not necessary the gearbox.

Some believe that no matter how full the sludge tube becomes, oil under pressure will always make its way to the big ends.

That's a theory, but the more widely accepted notion is that a plugged sludge tube will prevent oil from flowing to the big ends with catastrophic results.

It's also widely held that after a bike sits for a long time and is then restarted, dirt particles in the tube may break off and subsequently block critical oil ways in the engine, there being more risk for machines lubricated with non-detergent oil before storage and then drained and re-filled with detergent oil before re-starting.

So without splitting the cases, how does one know whether or not the sludge tube needs cleaning/replacing? Unfortunately we can't answer this question precisely, we can only make an educated guess based on service history and engine condition.

| More Sludge Deposit | Less Sludge Deposit |

| High mileage | Low mileage |

| Using non-detergent oil | Using detergent oil |

| Running dirty oil | Frequent oil changes |

| No external oil filter (as stock) | Fitting external oil filter |

A sludge trap service interval of twenty- to forty-thousand miles seems about right for a well-maintained machine in good condition and fitted with an external oil filter. Without an oil filter (stock) one could expect a significant reduction of those figures.

On the other hand, it has been said that fitting an external oil filter quadruples the life of an engine, and it's certainly not unreasonable to expect that a sludge trap would fill more slowly under those circumstances.

Some suggest hypothetically that sludge traps on '70 and onward 650 Twins might fill up more quickly due to those models sharing oil between primary chaincase and crankcase and on the basis that the clutch produces even more sludge (think shock absorber rubbers) than the engine itself.

Sludge tubes can be quite difficult to remove as there are two hurdles: removing the cap, and removing the tube itself. Tubes don't always survive the extraction, caps rarely. However, replacement sludge tubes are not expensive. Also, caps for them are now available which have either hex heads or hex key sockets instead of the more difficult to remove slotted head on the stock item.

There are two ways to remove the tube: smack it out and pull it out. Pulling it out may contribute to higher rates of tube survival.

What size tap to use for tube removal? LowBrow video (link above) suggests 3/8"-18 N.P.T. Kevin suggests EZ-Out number 6, drill size 13/32-inch.

When replacing the sludge tube be absolutely certain that its alignment hole is actually lined up for the flywheel bolt before inserting and tightening the bolt (Grand Paul).

Resources

Triumph Overhaul Manual Assembling the Flywheel

Triumph Overhaul Manual Assembling the Flywheel

TriumphRat.net MB walks us through Triumph "Flywheel Evolution"

TriumphRat.net MB walks us through Triumph "Flywheel Evolution"

TriumphRat.net Heavy & light flywheel photos ID'd "The T120 Crank/Flywheel amateur spotters field guide"

TriumphRat.net Heavy & light flywheel photos ID'd "The T120 Crank/Flywheel amateur spotters field guide"

TriumphRat.net Balance Factors "Dynamic ballance spec's. Does this look right"

TriumphRat.net Balance Factors "Dynamic ballance spec's. Does this look right"

TriumphRat.net A question of balance "Newly balanced crankshaft

"

TriumphRat.net A question of balance "Newly balanced crankshaft

"

The three flywheel bolts are one of the four places to use Loctite on a Triumph, and the only place to use red Locktite.

Triumph made numerous modifications to the "B"-range flywheels between 1963 and 1971. As summarized below, MB listed major changes in the Triumphrat.net thread "Flywheel Evolution" (link above).

Triumph made numerous modifications to the "B"-range flywheels between 1963 and 1971. As summarized below, MB listed major changes in the Triumphrat.net thread "Flywheel Evolution" (link above).

| Year | Change |

| 1963 - 1964 | Heavyweight flywheel - no timing slots |

| 1965 | Slot for TDC added |

| 1966 | Lightweight flywheel Balance factor unchanged (85%) |

| 1968 | Lightweight flywheel Slot for 38 degree max advance timing added First ones also had extra slots for timing plug re-positioned to the front of the engine, but later reverted to rear position after DU74052 |

| 1969 | Began w lightweight flywheel Reverted to heavyweight at NC.02256 - much like 1965 flywheel, but with 38 degree slot |

| 1971 | New flywheel - different profile Same balance factor and slots as 1969 flywheel Metric-sized timing side crank introduced at end of 1971 model year |

Resources

Workshop Manual (1969 650cc Twins) Section B37: Stripping & Reassembling the Crankshaft Assembly

Workshop Manual (1969 650cc Twins) Section B37: Stripping & Reassembling the Crankshaft Assembly

VictoryLibrary.com "Parallel Twin Crankshaft Balancing"

VictoryLibrary.com "Parallel Twin Crankshaft Balancing"

CycleWorld.com "Motorcycle Engine Balancing Act", Kevin Cameron

CycleWorld.com "Motorcycle Engine Balancing Act", Kevin Cameron

TriumphRat.net Mr. Pete on crankshaft balance factor

TriumphRat.net Mr. Pete on crankshaft balance factor

Britbike.com John Healy on crankshaft balancing

Britbike.com John Healy on crankshaft balancing

NOTE: the following information on crankshaft balancing and balance factor may contain factual and/or conceptual errors. It is based solely on my interpretation of forum threads and is pending further research.

The piston-rod-crankshaft kinetic energy of the parallel twin Triumph 650 is essentially the same as a single-cylinder engine - jumpy! Balancing a parallel twin for fewer vibrations (rider comfort) is likely to increase the stress on crankshaft and bearings, possibly to a destructive level. On the other hand, balancing for absolute minimum crankshaft/bearing stress results in intolerable vibrations for the rider.

A compromise is arrived at by manipulating the "balance factor". A balance factor is the percentage of the reciprocating weight of the crankshaft/rod/pistons that is used during the balancing procedure. The percentage given by the 1969 Triumph 650 Workshop Manual is 85%, which works out to a nominal 689 grams for a 650 twin.

For the parallel twin, a balance factor of around 63% is said to create the lowest possible stress to crankshaft components, but it also creates too many vibration at very uncomfortable frequencies for riders. Triumph specified a balance factor of 85%, which some say was later slightly lowered. It's possible that certain riders on certain machines could be perfectly comfortable with something like a mechanically kinder 75% balance factor.

There are potentially two sources of crankshaft vibration: reciprocal (up and down vibration) and rotational (side-to-side wobble). If a twin's crankshaft counterweights are out of balance from one side to the other it creates what's referred to as a "rocking pair". While a rocking pair can be completely balanced side-to-side, balancing up-and-down vertical vibration is, as already stated, a compromise between rider comfort (high balance factor) and reduction of stress to crankshaft and main bearings (lower balance factor).

Note that either static or dynamic balancing can use a balance factor to compensate for up-and-down imbalances, but only dynamic balancing can detect and correct a rocking pair.

It should also be noted that both static and dynamic balancing are done on a "dry" crankshaft. The addition of oil, including in the sludge trap, is said to effectively reduce the balance factor by 2 to 3%.

Finally, consideration should be given to whether the flywheel is of the heavy or the light type. The light flywheel is more prone to vibration than the heavy.

Resources

Triumph WS Manual Illustration of correct DS crankshaft seal orientation

Triumph WS Manual Illustration of correct DS crankshaft seal orientation

Triumph Overhaul Manual DS crankshaft oil seal

Triumph Overhaul Manual DS crankshaft oil seal

Britbike.com John Healy's explanation for orienting DS oil seal with spring towards primary chaincase

Britbike.com John Healy's explanation for orienting DS oil seal with spring towards primary chaincase

Lowbrow Triumph 650 Disassembly & Rebuild: Part 4 Timed Breather Disk Begins at: 18:25.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 4 Timed Breather Disk Begins at: 18:25.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 4 Crankcase Breathing Begins at: 17:55.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 4 Crankcase Breathing Begins at: 17:55.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 4 Orientation of DS Crankshaft Seal Begins at: 20:33.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 4 Orientation of DS Crankshaft Seal Begins at: 20:33.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 12 Orientation of DS Crankshaft Seal Begins at: :33.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 12 Orientation of DS Crankshaft Seal Begins at: :33.

When replacing the DS crankshaft oil seal, note that there are differing opinions floating around as to its correct orientation. In spite of both the Triumph Workshop and Overhaul manuals clearly indicating that the spring side of seal should face the engine sprocket, i.e. the primary chain case, there are some (including John Healy, Todd of Lowbrow, etc.) who say this is incorrect. See the BritBike.com and Lowbrow video links just above.

Important to note that due to a different crankcase breathing method, 1970 and 1971 models are not, and should not, be fitted with the DS oil seal, even though the Replacement Parts Catalogues for those years erroneously illustrate and list it.

Important to note that due to a different crankcase breathing method, 1970 and 1971 models are not, and should not, be fitted with the DS oil seal, even though the Replacement Parts Catalogues for those years erroneously illustrate and list it.

| Year | Engine Breathing | Engine/Primary | DS Crankshaft Oil Seal |

| 1963 - 1969 | Timed engine breather | No sharing of oil | Oil seal required. Springs to engine sprocket |

| 1970 - 1972 | Breathes via 3 holes btwn crankcase & primary chaincase | Oil is shared | NO oil seal should be used, even though erroneously shown in the parts books (J Healy) |

Resources

Workshop Manual (1969 650cc Twins) Section B40: Renew Main Bearings

Workshop Manual (1969 650cc Twins) Section B40: Renew Main Bearings

Service Bulletin Twin 14/72 "Metric Main Bearings"

Service Bulletin Twin 14/72 "Metric Main Bearings"

Lowbrow Triumph 650 Disassembly & Rebuild: Part 5 DS Main Bearing Inner Race, Remove Begins at: 38:25.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 5 DS Main Bearing Inner Race, Remove Begins at: 38:25.

Resources

Workshop Manual (1969 650cc Twins) Section B38: Refit Connecting Rods

Workshop Manual (1969 650cc Twins) Section B38: Refit Connecting Rods

Triumph Overhaul Manual Installing the Connecting Rods

Triumph Overhaul Manual Installing the Connecting Rods

Triumph Service Bulletin #317

"Self-locking nuts on big ends" (as shown in #7).

Triumph Service Bulletin #317

"Self-locking nuts on big ends" (as shown in #7).

TriumphRat.net: "Unit 650 con rods" Discussion on used connecting rods and connecting rods in general including balancing and torquing.

TriumphRat.net: "Unit 650 con rods" Discussion on used connecting rods and connecting rods in general including balancing and torquing.

BritBike.com "Conrod reconditioning" "Round out" your general knowledge of Triumph connecting rod lore.

BritBike.com "Conrod reconditioning" "Round out" your general knowledge of Triumph connecting rod lore.

It is very important to cover rod shanks for protection against nicks and scratches at all times. Nicks and scratches create stress points which will develop into cracks which will develop into disaster. Small nicks and scratches should be polished out with strokes made parallel with the rods using emery cloth and begining with #180.

Great care needs to be taken to mark and then reassemble connecting rods, caps, and shell bearings in their original locations and orientation. If components are new heed should be given to location if crankshaft was dynamically balanced.

Connecting rod caps and big ends usually have small punches or other marks that indicate how they are matched up. Often the marks are placed forward on the journals, but if they were assembled differently they should be re-assembled as they were. If a rod binds on the journal it's probably because the cap is turned around on the rod or the rod is turned around on the crank.

Never put oil between a shell and its rod or rod cap - this area should be absolutely clean and dry. Always use an appropriate assembly lube between a shell and the crankshaft journal.

The shell bearings are pressed by hand into the connecting rods and their caps. When the caps are installed on the rods, the tangs should end up on the same side of the big ends as shown in photo to right. Otherwise the caps are on backwards and the rod will bind on the journal as noted above.

Note that the tangs do not fix the shells in place, they center the shells in the rods and caps, making the shells slightly and equally proud at each end. This way, when the caps are tightened down the resulting "crush" wedges the shells tightly into the big ends, preventing them from spinning. The slight bevel on the shell ends helps compensate for any distortion that might occur from the crush.

Shell bearing clearance (diameter clearance) for the 1969 Triumph Bonneville is listed as 0.0005" - 0.0020" by the Workshop Manual. A generally accepted way to measure the actual clearance is with "Plastigauge".

The exact moment is somewhat unclear, but sometime in 1967, Triumph introduced new connecting rods (70-9525) that were thicker and stronger at the small end compared to old ones (E3606 / E3606T). While the old connecting rods had CEI 26 tpi. bolts, the new rods were fitted with UNF 5/16" X 24 tpi. bolts and self-locking nuts.

The exact moment is somewhat unclear, but sometime in 1967, Triumph introduced new connecting rods (70-9525) that were thicker and stronger at the small end compared to old ones (E3606 / E3606T). While the old connecting rods had CEI 26 tpi. bolts, the new rods were fitted with UNF 5/16" X 24 tpi. bolts and self-locking nuts.

The change in form necessitated a reduction in the connecting rod bolt torque from 28 lb.ft. for the old CEI bolts, to 22 lb.ft. for the new UNF bolts.

The Triump 650 Overhaul Manual says to measure the rod shank across the front or back 1" below the bottom of the wrist pin hole. According to the OHM, older style rods measure .550" while newer, thicker rods should measure .605". (Source: "List of Engine Changes Relating to Major Engine Work", Triumph 650 Overhaul Manual).

I've measured only one of my '69 T120R original rods - it was 0.606" on one side, and 0.596" on the other. Close enough for original.

Bringing the connecting rod fasteners to the proper degree of tightness can be accomplished by using either one (or both) of two methods: simply using a torque wrench, or by measuring a bolt's stretch as it is tightened.

The incomparable Mr. Pete (RIP) fills us in:

"Don't waste your time using Loctite on conrod nuts. Either tighten them up dry to 22lb.ft..s and risk thread damage on dry threads; or lubricate the threads with oil and measure the elastic bolt extension (0.004"-0.005"). Bolt extension is a better indication of bolt tension than torque measurement. The actual pre-load on the bolt is what is important.

The best way to tension rod bolts is to measure them with a micrometer. It will be easier if you flatten off the ends of the bolts. Measure the bolt before you start tightening. Use a torque wrench to tighten the bolt a little, and measure it again. Each time you tighten it, it should require a little more torque to move the nut. If the torque ever stops increasing,you have a problem and you should loosen the bolt and check its length. It should be the same as when you started or the bolt is junk.

When the bolt reaches 0.004"-0.005" extension, it's tight enough. If you plan to race it, go for 0.005" but no more.

If you can't get use of a micrometer, just tighten the nuts up dry with a torque wrench to 22lb.ft..s."

More on TriumphRat.net.So while there's near universal agreement that the bolt stretch method is best, it is only possible if one is able to make the measurements with the required accuracy. To get a better sense of what this entails, check out this Britbike.com discussion.

In actual practice the most common choice is probably to use a torque wrench to tighten the nuts "dry" to the correct torque spec. This should work fine for new, good quality bolts, but perhaps not as well for used bolts, especially when their previous stretch is unknown.

Resources

Workshop Manual (1969 650cc Twins) Section B32: Remove/Replace the Timing Cover

Workshop Manual (1969 650cc Twins) Section B32: Remove/Replace the Timing Cover

Triumph Overhaul Manual Timing Chest, Removing & Inspecting

Triumph Overhaul Manual Timing Chest, Removing & Inspecting

Triumph Overhaul Manual Timing Side Assembly

Triumph Overhaul Manual Timing Side Assembly

TriumphRat.net " Timing cover removal '72 T120R" RPW, Codeman, and Rambo tell you everything you need to know to accomplish this delicate procedure with aplomb.

TriumphRat.net " Timing cover removal '72 T120R" RPW, Codeman, and Rambo tell you everything you need to know to accomplish this delicate procedure with aplomb.

JRC Engineering "Triumph Timing Gears" Illustrations of timing marks for all year engines and special tools.

JRC Engineering "Triumph Timing Gears" Illustrations of timing marks for all year engines and special tools.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 4

Timing Chest Disassembly Begins at: 00:15.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 4

Timing Chest Disassembly Begins at: 00:15.

To remove the timing chest cover you must first remove the auto-advance unit. See link just above for tips on removing the AAU with or without the D484T special tool.

Note that unless care is taken, the idler wheel can fall off when the cover is removed. Placing the bike on its sidestand may help keep it in place. If it does fall off and none of the other gears have moved, simply replaced it.

If you're working on a '68, be sure to use puller GD523, not D484T. For details, see the Triumph Overhaul Manual.

If you're working on a '68, be sure to use puller GD523, not D484T. For details, see the Triumph Overhaul Manual.

The stock screws holding on the primary chaincase, gearbox, and timing chest covers are not Phillips - they are Posidrive screws. If you don't have a Posidrive screwdriver, pick one up and you'll be amazed at the difference it makes to use the proper tool. And, you won't be damaging the Posidrive screw heads.

The stock screws holding on the primary chaincase, gearbox, and timing chest covers are not Phillips - they are Posidrive screws. If you don't have a Posidrive screwdriver, pick one up and you'll be amazed at the difference it makes to use the proper tool. And, you won't be damaging the Posidrive screw heads.

One caution, though, the Posidrive heads grip so well that you may need to remind yourself to not over-tighten!

The cylinder head and the cylinder block have been removed and the transmission and gearbox have been disassembled prior to the steps below.

Early 1971 crankshafts use nut 70-4565, later '71 crankshafts used SAE thread nut 71-2877.

Early 1971 crankshafts use nut 70-4565, later '71 crankshafts used SAE thread nut 71-2877.

Resources

Workshop Manual (1969 650cc Twins) Section B34: Extract/Refit Valve Timing Pinions

Workshop Manual (1969 650cc Twins) Section B34: Extract/Refit Valve Timing Pinions

Workshop Manual (1969 650cc Twins) Section B41: Renewing Camshaft Bushes

Workshop Manual (1969 650cc Twins) Section B41: Renewing Camshaft Bushes

Lowbrow Triumph 650 Disassembly & Rebuild: Part 7 Checking Camshaft Bushings for Wear Begins at: 09:08.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 7 Checking Camshaft Bushings for Wear Begins at: 09:08.

BritBike.com 'Crank pinion gear' Discussion of techniques to remove the crank pinion gear

BritBike.com 'Crank pinion gear' Discussion of techniques to remove the crank pinion gear

Before removing any of the pinion gears, eliminate compressed valve spring pressure on the camshafts: either slack off the adjustors or remove the rocker boxes entirely.

Before removing any of the pinion gears, eliminate compressed valve spring pressure on the camshafts: either slack off the adjustors or remove the rocker boxes entirely.

The difficulty in removing the nut securing the crankshaft pinion gear is keeping the gear from moving. That is the topic of discussion in this BritBike.com thread. This group of posters propose and debate several methods:

Posters do mention that jamming the timing gears should only be done with great care. An air wrench works well, and if the clutch and gearbox components are still in place, a clutch locking tool with a handle long enough to rest against the DS passenger footrest will work very nicely.

Inlet camshaft nut 70-1463, and Exhaust camshaft nut 70-4563 have left-handed threads. (Ref.33/34 Fig.1 P.13 #7)

Inlet camshaft nut 70-1463, and Exhaust camshaft nut 70-4563 have left-handed threads. (Ref.33/34 Fig.1 P.13 #7)

Once again, the difficulty in removing the pinion gears is to keep them from moving. Using an air wrench eliminates this problem, or, just wait until the cases are parted and then grip the camshafts one at a time by their lobes in a soft-jawed vice and wrench off the nuts.

Resources

Workshop Manual (1969 650cc Twins) Section B35: Valve Timing

Workshop Manual (1969 650cc Twins) Section B35: Valve Timing

Resources

TriumphRat.net Patent Plate Removal

TriumphRat.net Patent Plate Removal

BritBike.com 1967 Bonneville kickstart stop More useful patent plate tips from TR7RVMan in this kickstart thread

BritBike.com 1967 Bonneville kickstart stop More useful patent plate tips from TR7RVMan in this kickstart thread

The patent plate mounted on the timing chest cover often gets polished to a shiny blank. If so, or if it has been damaged, spare replacements are available. Note that some repro patent plates are embossed and others are not.

The trick to changing the patent plate is removing the twisted pins that hold it on. Being hardened, the pins are somewhat brittle, so care must be taken to not break them off, making extraction even more difficult. The links above describe the most popular techniques and also cover what to do should things go wrong. Kadutz, on TriumphRat.net wraps it up nicely.

Resources

Workshop Manual (1969 650cc Twins) Section B22: Removing and Refitting the Pistons

Workshop Manual (1969 650cc Twins) Section B22: Removing and Refitting the Pistons

Workshop Manual (1969 650cc Twins) Section B24: Inspecting Pistons & Cylinder Bores

Workshop Manual (1969 650cc Twins) Section B24: Inspecting Pistons & Cylinder Bores

Workshop Manual (1969 650cc Twins) Section B25: Table of Suitable Rebore Sizes

Workshop Manual (1969 650cc Twins) Section B25: Table of Suitable Rebore Sizes

Workshop Manual (1969 650cc Twins) Section B26: Piston Identification

Workshop Manual (1969 650cc Twins) Section B26: Piston Identification

Hermit.cc Removing Pistons

Hermit.cc Removing Pistons

BritBike.com: "T120 Pistons" (Manufacturers)

BritBike.com: "T120 Pistons" (Manufacturers)

BritBike.com: "New pistons question" John Healey checks in on piston taper and diagnosing piston problems.

BritBike.com: "New pistons question" John Healey checks in on piston taper and diagnosing piston problems.

Franz and Grubb "Triumph 650 piston installation notes"

Franz and Grubb "Triumph 650 piston installation notes"

TriumphRat.org "Stuck Pistons" Methods for removing stuck pistons

TriumphRat.org "Stuck Pistons" Methods for removing stuck pistons

New Hepolite pistons were introduced in 1969. The new pistons had a heavier crown and used shorter grudgeon pins with heavier cross sections.

New Hepolite pistons were introduced in 1969. The new pistons had a heavier crown and used shorter grudgeon pins with heavier cross sections.

So, you landed that amazing "barn-find" but can't get the cylinder block off because the pistons are stuck. Here's a summary of methods to free stuck pistons from TriumpRat.org (see link just above in Resources for full details):

Reputedly the three best rust/corrosion freeing solutions are:

In conjunction with soaking:

Resources

Lowbrow Triumph 650 Disassembly & Rebuild: Part 2

Gudgeon Pin & Piston Removal Begins at: 24:40.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 2

Gudgeon Pin & Piston Removal Begins at: 24:40.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 2

Small End Bushings Begins at: 27:00.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 2

Small End Bushings Begins at: 27:00.

Hermit.cc Simple gudgeon pin extraction tool Photo.

Hermit.cc Simple gudgeon pin extraction tool Photo.

When working around the connecting rods, use plenty of padding to protect them from the sharp edges of the crankcase and the base studs.

When working around the connecting rods, use plenty of padding to protect them from the sharp edges of the crankcase and the base studs.

Gudgeon pins (wrist pins) should move freely (but without side-to-side play) in the small end bushes of the connecting rods, and be of a tighter fit in the pistons, Sometimes they can be removed with just thumb pressure at room temperature, but other times it requires a little heat on the piston: 100C (212F) using a digital laser thermometer or the spit sizzle method. Chilling the gudgeon pins can also help.

If a wrist pin won't come all the way out even after heating the piston, you can use a simple extraction tool fashioned from a threaded rod, a couple short lengths of pipe, and some nuts and washers. See link just above.

Todd uses a drift to remove a gudgeon pin in the Lowbrow video just above, but as noted in the WS Manual, this is NOT recommended due to the possiblity of connecting rod damage.

Todd uses a drift to remove a gudgeon pin in the Lowbrow video just above, but as noted in the WS Manual, this is NOT recommended due to the possiblity of connecting rod damage.

In rare cases when the small end bushes require reaming that is best done with the connecting rods removed from the engine so that they can be reamed perfectly perpendicular to the connecting rod.

In rare cases when the small end bushes require reaming that is best done with the connecting rods removed from the engine so that they can be reamed perfectly perpendicular to the connecting rod.

Skirt clearance is the amount of space between pistons and cylinder walls. Insufficient skirt clearance means near certain piston seizure.

It's possible to measure the clearance with feeler gauges but a more accurate method is to measure piston outside diameter with a micrometer and cylinder inside diameter with a bore gauge and subtract as follows:

Piston Skirt Clearance = Cylinder ID - Piston OD

The spec given by the 1969 Triumph Workshop Manual for piston clearance is 0.0106/0.0085 inches at the top of the piston skirt and 0.0061/0.0046 inches at the bottom. Top and bottom clearances are given because pistons back in the day were slightly tapered. John Healy offers us this explanation of the reason for the taper and why it's no longer of much concern.

Modern pistons are manufactured differently and have little if any taper, so clearance may well be the same top and bottom - all to be determined by careful measurements of course.

I think it's safe to say that when using modern pistons with effectively no taper, a top and bottom piston clearance of 0.005 to 0.0055 inches would be very acceptable.

Usually reliable sources have said on forums that clearances of 0.0041, 0.0037, and even less work for them, but for a variety of reasons those clearances are not apt to succeed on every engine built by any builder. The bottom line is beware of not enough clearance because the result is piston seizure.

Too much clearance? A noisier engine and probably increased wear to pistons, rods, etc.

Often gudgeon pins can simply be pushed in with thumb pressure. If not, either chill the wrist pin or gently warm the connecting rod small end where fit is likely the tightest.

Replacing circlips:

Resources

Workshop Manual (1969 650cc Twins) Gen Data & Sec B23 (obsolete)"

Workshop Manual (1969 650cc Twins) Gen Data & Sec B23 (obsolete)"

Triumph Overhaul Manual (1967) Ring Gap (obsolete, see below)

Triumph Overhaul Manual (1967) Ring Gap (obsolete, see below)

Triumph Service Bulletin #323 "Piston Ring Gaps" (obsolete, see below)

Triumph Service Bulletin #323 "Piston Ring Gaps" (obsolete, see below)

Triumph Service Bulletin (Twin) 1971 "Piston Ring Replacement"

Triumph Service Bulletin (Twin) 1971 "Piston Ring Replacement"

Triumphrat.net "DIY Piston Ring End Gap Tool".

Triumphrat.net "DIY Piston Ring End Gap Tool".

Triumphrat.net "Orientation of cast iron rings, Shippy.

Triumphrat.net "Orientation of cast iron rings, Shippy.

Franz and Grubb "(Grant) Triumph piston ring installation and break-in"

Franz and Grubb "(Grant) Triumph piston ring installation and break-in"

Different Triumph docs through the years gave different ring gap specifications. The last revision was made in 1971.

| Document | When | Recommendation |

| Triumph Service Bulletin Twin 11/71: Piston Ring Replacement | 1971 | 0.012 - 0.018 |

| Triumph Overhaul Manual: Page 10, Step (d) | 1967 | 0.010 - 0.017 |

| Triumph Service Bulletin #323: Piston Ring Gaps | 1967 DU44934 H49837 | 0.015 - 0.020 |

| Workshop Manuals, Gen Data and: Section B23 | 1963 - 1969 | 0.010 - 0.014 |

The important thing is to have sufficient gap: a little too much isn't critical, but too little can result in the rings binding up and scoring the cylinder walls or even seizing a piston in extreme cases.

Keep in mind that ring gap determination must be proportional to cylinder size, an important consideration if installing so-called big bore kits. Dave gives a standard formula for gap calculation based on cylinder size here. Don offers a slight variation here. That thread is worth reading in its entirety as it includes much good advice.

When filing ring gaps the ends should be kept parallel with the ring's radius. If using a file consider doing as Don does which is to hold the file in a vice and not the rings. Emory paper can also be used: some move the paper through the ring and others move the ring across the paper (see "DIY Piston Ring End Gap Tool" just above in resources for an interesting take on this).

Always install rings from the top and observe correct order and cylinder for each ring. Rings usually have a marking that indicates which side goes up. Orient the oil scraper rings with their gaps at six o'clock, and the compression ring gaps at three o'clock and nine o'clock.

One advantage of using ring compressors is that the orientation of the ring gaps doesn't change during installation.

Also See: John Healy on "dry" ring assembly.

Resources

Triumph Overhaul Manual Assembling Pistons, Pins, Rods, Cylinder Barrel

Triumph Overhaul Manual Assembling Pistons, Pins, Rods, Cylinder Barrel

Workshop Manual (1969 650cc Twins) Section B20: Inspecting Tappets & Guide Blocks

Workshop Manual (1969 650cc Twins) Section B20: Inspecting Tappets & Guide Blocks

Workshop Manual (1969 650cc Twins) Section B21: Renewing the Tappet Guide Blocks

Workshop Manual (1969 650cc Twins) Section B21: Renewing the Tappet Guide Blocks

Workshop Manual (1969 650cc Twins) Section B19: Removing and Replacing the Cylinder Block and Tappets

Workshop Manual (1969 650cc Twins) Section B19: Removing and Replacing the Cylinder Block and Tappets

The Bonneville Shop "The Brain of Your Triumph B Range Engine- the Camshaft" Triumph camshafts and tappets through the years, explained.

The Bonneville Shop "The Brain of Your Triumph B Range Engine- the Camshaft" Triumph camshafts and tappets through the years, explained.

J.R.C. Engineering "Understanding Triumph Tappet Blocks and Pushrod Tubes" Complete rundown of tappet blocks & PRTs on Triumph models from 1945-1982

J.R.C. Engineering "Understanding Triumph Tappet Blocks and Pushrod Tubes" Complete rundown of tappet blocks & PRTs on Triumph models from 1945-1982

Resources

Britbike.com "Which Comes First, Piston or Bore?" Long, interesting thread, with broad con census on best procedure to follow, and many tips on re-boring a Triumph unit 650.

Britbike.com "Which Comes First, Piston or Bore?" Long, interesting thread, with broad con census on best procedure to follow, and many tips on re-boring a Triumph unit 650.

Britbike.com "Mapping the bore" An experienced hand explains how to prepare for a cylinder re-bore. Learn some very interesting facts about cylinder topography and piston shape in the process.

Britbike.com "Mapping the bore" An experienced hand explains how to prepare for a cylinder re-bore. Learn some very interesting facts about cylinder topography and piston shape in the process.

Britbike.com "Dry Ring Installation" A repost of John Healy describing the complete Triumph 650 honing process, followed by his take on "dry" ring assembly - or, as Mr. Healy would prefer, "dri-er" ring assembly.

Britbike.com "Dry Ring Installation" A repost of John Healy describing the complete Triumph 650 honing process, followed by his take on "dry" ring assembly - or, as Mr. Healy would prefer, "dri-er" ring assembly.

Britbike.com "Further to preparing the cylinder..." Mr. Healy offers more fine points on honing Triumph 650 cylinders, and dives deeper into the machinations of air-cooled machines.

Britbike.com "Further to preparing the cylinder..." Mr. Healy offers more fine points on honing Triumph 650 cylinders, and dives deeper into the machinations of air-cooled machines.

Rarely does one see Triumph 650 cylinders bored out more than 60 thousandths. It is said that the cylinder walls are in places quite thin, and overbores more than that are not reliable.

That being said, my Bonnie went around 12,000 miles on an overbore of 100 thousandths before she got a new set of cylinders at 86,000 miles.

The following table shows the effect of overboring on the displacement of the Triumph 650 engine.

Before having your Triumph 650 cylinders honed, take the time to read the above posts by John Healy on the tried and true methods of getting a good re-bore and a good break-in.

After honing, cylinders need to be washed and scrubbed with a brush in hot water with detergent to remove ALL remaining abrasive material. It can't be over-emphasized how important this is. Wash them and wash again. And again. Foreign materials left behind may score the cylinders or block oil-ways, ruining the entire job with potentially catastrophic results.

When thoroughly clean, dry the cylinders with a clean cloth and then apply light coat of oil.

Resources

Workshop Manual (1969 650cc Twins) Section B21: Renewing the Tappet Guide Blocks

Workshop Manual (1969 650cc Twins) Section B21: Renewing the Tappet Guide Blocks

BritBike.com "Refitting tappet guide block, T140" TR7RVMan nails the drill (pertains also to T120)

BritBike.com "Refitting tappet guide block, T140" TR7RVMan nails the drill (pertains also to T120)

BritBike.com "Tappet block installation" Koan58 offers a method for precision alignment.

BritBike.com "Tappet block installation" Koan58 offers a method for precision alignment.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 2

Tappet Blocks, Removal Begins at: 18:00.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 2

Tappet Blocks, Removal Begins at: 18:00.

To remove or replace the tappet guide blocks it's essential to use the special drift: Service Tool 61-6008. It takes substantial blows with something like a little two-pound sledge to drive the blocks in. While a block is moving, it can be steered quite easily by twisting on the tool's hatch-marked handle.

When driving the guide blocks in or out, remember that they are not perfectly vertical - they are set at a slight angle. Adjust your drift accordingly or risk damaging the block's skirts. Ask me how I know.

When driving the guide blocks in or out, remember that they are not perfectly vertical - they are set at a slight angle. Adjust your drift accordingly or risk damaging the block's skirts. Ask me how I know.

On his DVD, Hancox says to line up the hole in the blocks with the locator screw hole in the cylinder block. For an amateur like myself that's not a sufficient guarantee that the tappet holes will end up exactly parallel to the camshaft. Instead I try to concentrate on the alignment of the tappet holes with the camshaft - if that is acheived the locator screw will line up for sure.

Being relatively narrow, the tappet blocks are difficult to line up perfectly by eye. A straight edge placed against the block helps greatly.

Being relatively narrow, the tappet blocks are difficult to line up perfectly by eye. A straight edge placed against the block helps greatly.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 2

Tappets, Remove & Inspect Begins at: 13:20.

Lowbrow Triumph 650 Disassembly & Rebuild: Part 2

Tappets, Remove & Inspect Begins at: 13:20.

The tappets ("lifters", "followers") ride up and down in the tappet block, operating the pushrods above them as they themselves rise and fall with the rotation of the camshaft lobes beneath them.

Exhaust tappets with an oil feed must be installed in the tappet block with their "flats" ("C" in illustration at right) facing outward.